Testing times

27 March 2024Graham Ormondroyd from The BioComposites Centre asks why should testing take so long?

Twenty degrees centigrade and 65% relative humidity (RH) are numbers that are stamped on the brains of any wood scientist. These are the conditions that wood and wooden products should be stored at until an equilibrium of moisture between the atmosphere and the samples are achieved (ie, the weight does not change over a 25- hour period). This is laid down in the testing standards for timber and timber products (ie, BS EN 319:1993). Wood is anisotropic and shrinks and swells at different rates in different directions and whilst wood composites negate this and become more orthotropic in the whole, the individual wood elements within the composites will still be anisotropic.

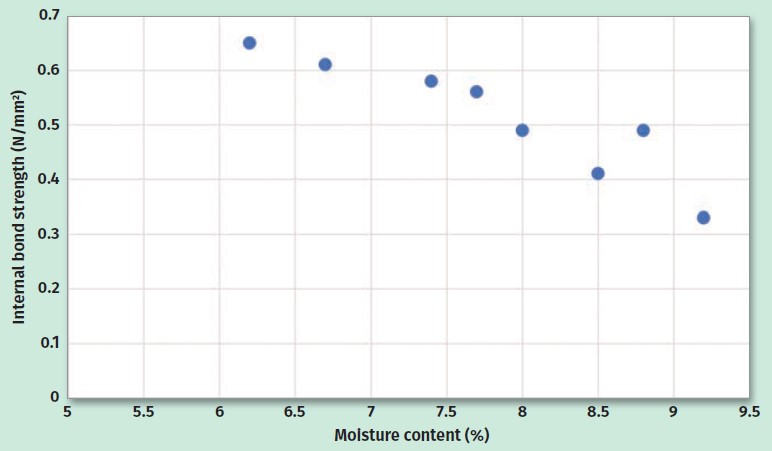

As wood or wood composites shrink and swell and the moisture content changes, this influences the properties of the composites. In fact, not only does the moisture content influence the wood strength and stiffness but it could also have an effect on the resin.

Recent work from Portugal has shown that an E1 commercial MDF board loses nearly half its internal bond strength with an increase of just 3% moisture content. So, this shows that the conditions that the board are tested in need to be consistent to test different boards equitably.

The problem is that it takes time to condition samples. The larger the sample, the longer it takes to condition – it can be two weeks or longer to condition panel samples before they reach their equilibrium moisture content, and this will delay getting the analysis and results back to the client.

But why 20°C and 65% RH? Some would say that we should be testing at a defined moisture content and not to environment conditions to give the level playing field that is needed for fair testing. However, at the point of service the different products will experience the same conditions and so this was seen as the fairer way to condition.

Anecdotally we have always been told that the parameters were set because these were the average temperature and RH for homes when the standards were being written, but I have not been able to find evidence to support this. However, this does make sense, that you would want to test your samples as close to the condition that they will be used in as possible.

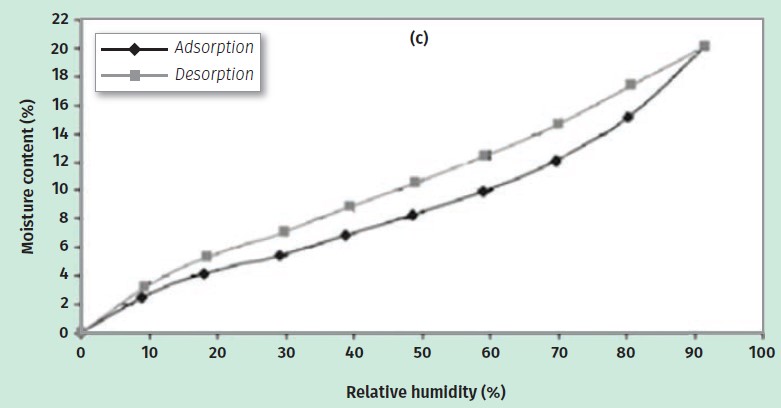

A note on drying or wetting to reach equilibrium. Whilst there is not room here to fully explain the phenomenon of ‘hysteresis’, there are differences between the moisture content achieved in wood conditioned at the same RH depending on whether it has been dried down and wetted up. There are many academic papers showing hysteresis in wood. For example, with pine the difference between the wetting state and the drying state can be as much as 5% and this can have a significant effect on the IB strength of panel samples.

It is well known that when testing either timber or wood-based panels it is imperative to condition all samples to a constant temperature and RH, to give a level playing field when you are testing different products against one another, and that 20°C and 65% RH is required when comparing to standards.

This adds time to the test regime, time for the samples to sit and take up or give out moisture. However, it will give you results that will be consistent with other tests and standards, so please, bear with us whilst we give you the best possible and most usable results for your products and innovations.