Ready for the future

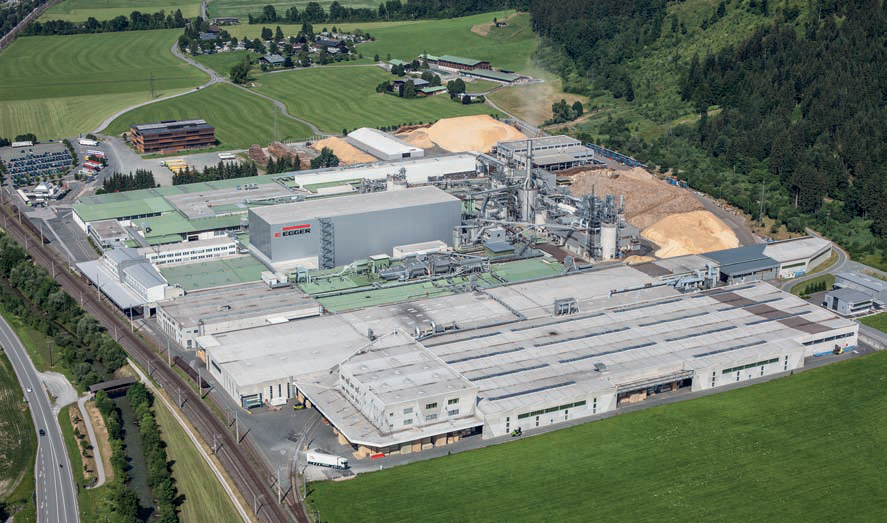

3 March 2016The EGGER Group, headquartered in St Johann in the Austrian Tyrol, is one of the leading international wood based panel manufacturers. Founded in 1961, the family-owned company now has 17 European production plants, with around 7,600 employees worldwide, and it continues to invest in its future

Global customers of this wood based materials manufacturer include those in the furniture industry, wood and flooring distribution, building markets and DIY.

In order to strengthen its market position, Egger says it is continually working on further developments for its product portfolio. These include investments in plants, technology and employees - in addition to the innovative thinking which it says is promoted group-wide.

This company is always investing in the modernisation and expansion of its plants; and in new locations. It says this ongoing investment allows it to meet current customer and market requirements. During 2014/15, the group says it ensured stable development with investments totalling €263.3m. Of this, €60.3m was spent on maintenance and €203m on growth.

The Gagarin plant

One of the largest projects of last, and this, business year is the expansion of Egger's plant in Gagarin, Russia. The SOFIA project started in 2013 and the total investment will be approximately €200m.

Half this money will be spent on construction and infrastructure, while a recently installed biomass power station, once completed, will produce heat for drying wood fibres.

The core of the first expansion phase is an ultra-modern MDF production facility. It will start operating in the second half of 2016, and will produce 350,000m3 of boards, annually.

After the investment, the Egger Gagarin plant will cover 650,000m2. Given the high energy consumption needed to manufacture MDF, a new electricity sub-station and a new gas supply are also under construction.

In addition, Egger has installed an evaporation plant, a sewage plant and a modern water treatment plant to protect the environment. With these facilities, the panel manufacturer says it is able to run operations without waste water.

The work on the MDF production facility in Gagarin is running at full speed; the new sub-station, gas supply, debarking facility, disc chipper and parts of the water treatment plant started operation in December 2015.

The expansion has created 350 new jobs in the Russian region of Smolensk.

The flooring production facility was one of the first areas to benefit from the investment and started operation in summer 2015.

Previously, this production was located in the Egger plant in Brilon, Germany, before being moved to its Russian location.

As Egger sees eastern Europe and Russia, in the medium term, as strong growth markets for laminate flooring, it took the decision to manufacture these products locally, driven by regional demand. This has been made possible by locating the new production facility in Gagarin.

High-end surfaces

During 2014/15, the decorative products area for furniture and interior design saw investment in a revolutionary high-gloss/matt lamination facility in Brilon to manufacture the new PerfectSense product range.

With this innovation, Egger says it has raised its melamine faced boards - as well as the look, feel and robustness of its surface textures - to a new level of quality.

The company says that this new product category provides high-gloss, or matt-finished boards in premium designs and uses Egger's own tried and tested quality MDF.

Together with specialist finishing machinery supplier Hymmen of Germany, Egger developed a special coating process with UV paint technology (CCI = Calender Coating Inert).

This innovative method elevates surfaces to a visual and tactile level that was previously only reserved for a few high-end surfaces, says Egger, adding that the innovative finish ensures that PerfectSense fits in its own category among wood based products.

In this way, Egger says it makes the highest quality surfaces easily available, as well as economically attractive.

The company says that these finished surfaces are suitable for high traffic areas and are particularly scratch-resistant and robust. On the one hand, it says, consumers profit from these properties by enjoying high quality furniture surfaces over the long term.

On the other hand, says Egger, the high resistance and strength properties benefit furniture manufacturers and fabricators by providing security during the processing and fitting of PerfectSense products.

PerfectSense Gloss is characterised by an exceptional ultra-gloss surface and is said to clearly stand out against other high-gloss surfaces.

Egger says that its MDF provides a consistent core for these exceptional characteristics. Matt finishes, in contrast to high gloss finishes, are currently 'up and coming' in exclusive interior design, with matt surfaces being associated with high value and predominantly used in luxury furniture production.

The new surface PerfectSense Matt stands out from other matt surfaces thanks to its high quality finish, says Egger. The surface of the matt innovation from the company has no-fingerprint properties and feels smooth and velvety. The look and feel are in perfect harmony, it says.

Egger says it has always been at the forefront of new processes for adding value to its panels and has come a long way since its foundation in 1961, when it built its first particleboard plant.

This turned out to be the first of several such lines. In 1995, the company bought a thin MDF plant in Bevern, Germany and this was just the beginning for Egger in MDF.

The company now has its own factories in several countries, from the UK in the west to Russia in the east.

Value-adding has been a core interest for Egger and the company today shows no sign of slowing down in trying to achieve its vision of being "the leading brand for wood based solutions in Europe".