Ireland bound

27 November 2023Geoff Rhodes, independent consultant and former long-serving marketing and sales director at MEDITE looks back 40 years to Medford Corporation’s multi-million dollar investment in the Clonmel factory

This overview sets the scene of what was to become one of the most significant investments in European panel product manufacturing – the US$50m MDF plan in Clonmel, Co Tipperary, Ireland, which started production on September 28, 1983.

Sometime prior to 1910, Henry F Chaney arrived by train in Eugene, Oregon, bought a horse and then rode off into the timberrich territory of south-west Oregon looking for potential timberland acquisitions for his family.

Mr Chaney subsequently became the vice-president for west coast affairs of Baker Fentress and Company. Baker Fentress was a banking house in Chicago that pioneered timber-secured bonds after the turn of the century. Between 1909 and 1927 it assumed nearly US$100m-worth of bonds for almost 100 major lumber companies.

Calvin Fentress started at the firm in 1902 eventually becoming the president and in 1920 the firm’s name was changed to Baker Fentress and Company. Medford Corporation was a successor company to one of the Baker Fentress financed lumber companies that failed during the 1920s. It formed a bond holders committee to exchange the bonds for stock in the new company – Medford Corporation (Medco).

By 1979, Medco had become a mediumsized forest products company with sales over US$125m, more than 2,000 employees, and a very strong balance sheet.

Wood chip exports to Japan through Marubeni Corporation, Lumber and Plywood production and secondary manufacturing of panel products, including MDF, were all part of the commercial mix.

Its real financial strength was in part due to its significant timber holdings, which were carried on the books at original cost as low as US$1/thousand board feet when current market value was as high as US$300/ thousand board feet.

The company managed the timberlands to only harvest the volume equal to the growth each year. As the value of the timber increased from year to year, there were always vultures around, who would like to buy the company and liquidate it for cash.

The reason this did not happen to Medco was that Baker Fentress had control of nearly 50% of Medco shares. In addition to Medco, Baker Fentress had many other timber holdings, which were sold off over the years partly because they did not have the control they had with Medco. These holdings became the core of some of the giants of the modern US forest products industry.

Management and decision making at Medco evolved over the years as it became a more locally managed autonomous company.

In the early years it was directly managed by Baker Fentress and by the late 1970s was in the third generation of local management, as Bob Higgins took over as president from Russ Hogue, forming his management team, and looking for opportunities to leave his legacy on the company.

The open question at the time was in what way to invest into the future? Pulp, paper or perhaps in new technology opportunities, with long term potential?

There was never any doubt that the Medford management knew that big decisions needed Baker Fentress’ approval and their job really was to make sure that Baker Fentress had the most complete information and recommendations to make those decisions.

Into the late 1970s the Medco board of directors had three members who were sons of Calvin Fentress Sr as well as the son of Henry Chaney who was chairman. An observation over the years was that although Baker Fentress had many other investments, it seemed to have a special attachment to Medco and particularly to the timber, so it was not a big surprise when they were not completely adverse to an adventurous project in the Republic of Ireland.

IRELAND – AN OPPORTUNITY

During the late 1970s the Irish government was addressing solutions to two problems.

First was finding an outlet for the pulpwood being generated by its plantation forests and, second, finding uses for the byproducts of its infant sawmill industry. The Irish Forestry Department along with the Industrial Development Authority (IDA) recognised that there would be a need for a new industry by the end of the decade.

The IDA did a thorough study looking at many product areas, eventually reduced it down to five, including MDF and then carried out a determined marketing campaign, mainly in North America, to find a company that could establish a significant wood processing operation in Ireland.

The IDA wanted a company with good financial strength, strong technical experience in its product area, an established market, a potential for added value in Ireland and a comfortable sized operation for the available timber. Medco was a target in this search and received an extensive prospectus in late 1979, which was quickly labelled the ‘SHAMROCK CAPER’ by Ted Bauer, the Medco Medite MDF sales manager.

While this was going on, the original Medco Medite MDF mill (approved for construction in 1972) had started its pioneering 150,000m3 operation in Medford Oregon in May 1975 and the business was growing well. Export markets were sought and gradually developed with Canadian sales being handled by Weldwood in Vancouver and other overseas markets being handled through Seaboard Lumber Sales and its network of international overseas offices.

The first small shipments of MDF to the UK (to Phoenix Timber and Keizer Venesta) and to mainland Europe (Het Hout De Bruyn in NL) started in 1976, with the small quantities of Medite MDF taken by rail from Medford to Vancouver and then shipped utilising Seaboard’s 30,000 tonne bulk carriers to Tilbury and elsewhere on the continent.

Over the next three years, and by 1979, this export trade in MDF from the US to the UK and Europe had built to around 12,000m3 with a variety of importers.

In 1978 Ted Bauer came to the UK to deliver an inspiring conference paper at the FIDOR conference in Eastbourne – whetting the appetite of the delegates to the potential for MDF in the UK and Europe, based on the American experience so far.

At the time, Medco was made up of three business segments – the traditional lumber, plywood and veneer operations, kitchen cabinets and MDF. There was little potential for growth in lumber and plywood because of a shrinking timber supply and the cabinet division was already approaching national distribution of its products, so that left MDF as the most likely growth possibility.

In 1979, a discussion with Bob Higgins and the IDA took place and the Medco management decided it had an obligation to look at any significant opportunity in MDF. Mr Higgins then made the decision to send Paul Steele, the company accountant, and Ted Bauer, the MDF sales manager, to Ireland to see what could be learnt.

The two men travelled to Ireland in early May of 1980 and spent a week with the IDA and Forestry Department. They were given an extensive review of the development of Irish forestry, the projections of future wood production and the current state of the industry and toured the southern part of the country looking at forestry and sawmill operations.

A follow-up trip in July 1980 took place with a six-person team, so Medco could study all the issues of an Irish project, including what a timber supply contract might look like, Irish financing, government incentives, tax structure, corporate structure, building sites, construction contractors, transportation both for timber as well as product going out, market research and many other topics.

Paul Steele then did most of the work compiling a report for presentation to the board of directors at their October meeting in Chicago. John Wadsworth of BIS in the UK, who was a panel products market researcher well respected in the industry, was also brought in to report on the development and future potential of European markets for MDF.

The big issues were timber supply, markets for MDF and cost. The timber contract was to be with the Republic of Ireland and as such would be ratified by the Dáil, giving it the status of a national treaty. There was caution about the fibre quality of the Irish timber, which was mainly Sitka spruce, so Medco arranged to ship several truckloads of Sitka spruce and then planned a test production run in the Medford mill, which actually produced a very good product.

The company recognised that marketing and generating sales in volume of this new product across Europe quickly was going to be one of the biggest challenges.

A follow-up meeting was scheduled in early December 1980 in Medford, to review the project further and then make a final decision.

At the December meeting in Medford, the conclusion was a ‘go’, and Paul Steele left immediately for Dublin where he spent the rest of the year finalising all the big issues – the timber contract, the IDA agreement, bank financing, corporate structure and sales and marketing arrangements and so on.

Medco formally announced the European project in March of 1981. This US$50m project went out on ‘the wire’, was reported in all the trade press and Seaboard also hosted a reception in London to mark the moment with the UK trade.

It was obvious to Paul Steele very early on that if Medco was going to go ahead with this project that someone was going to have to move to Ireland. There were others at Medco who would have liked the job but would not have agreed to move on a longterm basis. Mr Steele’s wife accompanied him on the December trip to get a feel of what a move might be like and they stayed over the Christmas holiday, which was a good experience. By the autumn of 1981 they were residents of Ireland.

Clonmel was selected as a central point and good location for the plant within the expanding forest resource in Ireland, and with good access to the ports of Cork, Waterford, and Dublin.

CONSTRUCTION BEGINS

Construction began later in 1981 and state-of-the-art equipment was supplied by a host of international vendors – the forming line and multi-daylight press from Washington Iron Works (US), refiners from Sunds Defibrator (Sweden), sanding line from Steinemann (Switzerland) and many more.

The company employed an outstanding team of professionals and any start up challenges were successfully overcome, leading to the first production run and first MDF board being produced on September 28, 1983, at 1.32pm precisely.

On April 27, 1984 the company held the official opening ceremony and the minister for Forestry and Fisheries, Paddy O’Toole represented Ireland, along with the Mayor of Clonmel, Tommy Boyle. Bob Higgins and Russel Houge came from Medford, US. Senior representatives of the timber trade from the UK, Continental Europe and Ireland were present. The Bishops of both the Church of Ireland and the Church of England were in attendance, to bless everything created and for the future. It was a very special day.

The very first UK contract in 1983 for the Clonmel facility (MOE-0001) was with James Latham for Woodberry Brothers and Haines, a furniture manufacturer in the west of England. No FSC, CE marking or E1 in those early days – that all came later.

At that time MDF was not fully understood nor accepted in the marketplace, but with the help of American colleagues and the pioneering spirit and effort of the UK and European sales and marketing teams, to grow and expand the market, MEDITE of Europe was able to achieve full annualised production of 150,000m3 within the first year of operation.

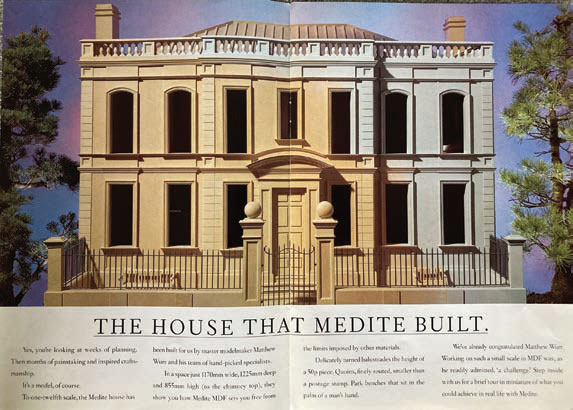

Creative advertising played a key and integral part in stimulating the market in those early days, with visuals and straplines used such as ‘MEDITE leaves the others sanding’ and ‘Do your designers suffer from wooden thinking’ and the ‘MEDITE House’ campaigns being good examples.

The next steps were to focus on the development of a range of value-added MDF products, which positioned MEDITE as a premium supplier, coupled with its international technical and marketing expertise.

In the next few years, MEDITE experienced a period of strong market growth, culminating in the company doubling the capacity of the Clonmel facility.

The rest as they say is history…

• Acknowledgements and thanks: Piecing together this overview would not have been possible without input from Paul Steele, Rory Kirwan, John O’Brien, Con Little, Peter Parker, Peter Stewart, Ed Annan, Malcolm Cowley, Peter Travis and Chris Sutton

Many striking promotional campaigns, including the MEDITE house, came from the creative marketing team

Many striking promotional campaigns, including the MEDITE house, came from the creative marketing team

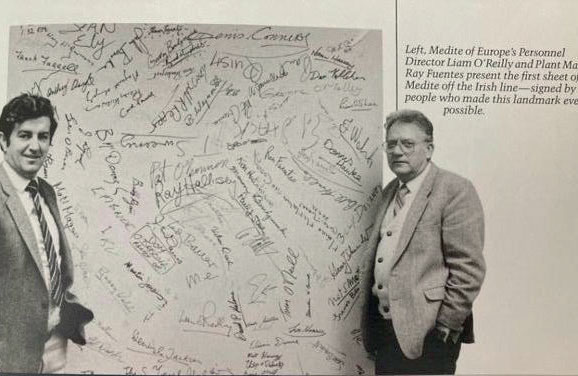

Liam O’ Reilly, personnel director MEDITE of Europe and Ray Fuentes, plant manager from the US, presenting the first sheet of MDF off the line at Clonmel

Liam O’ Reilly, personnel director MEDITE of Europe and Ray Fuentes, plant manager from the US, presenting the first sheet of MDF off the line at Clonmel

One of Seaboard’s bulk carriers (FARO - 30,000 tonnes) coming up the River Thames to Tilbury, having sailed from Vancouver, down the west coast of the US, through the Panama Canal and then right across the Atlantic to bring cargo (including MEDITE MDF) to an awaiting market place. A voyage of almost four weeks

One of Seaboard’s bulk carriers (FARO - 30,000 tonnes) coming up the River Thames to Tilbury, having sailed from Vancouver, down the west coast of the US, through the Panama Canal and then right across the Atlantic to bring cargo (including MEDITE MDF) to an awaiting market place. A voyage of almost four weeks