From machine factory to Anthon 4.0

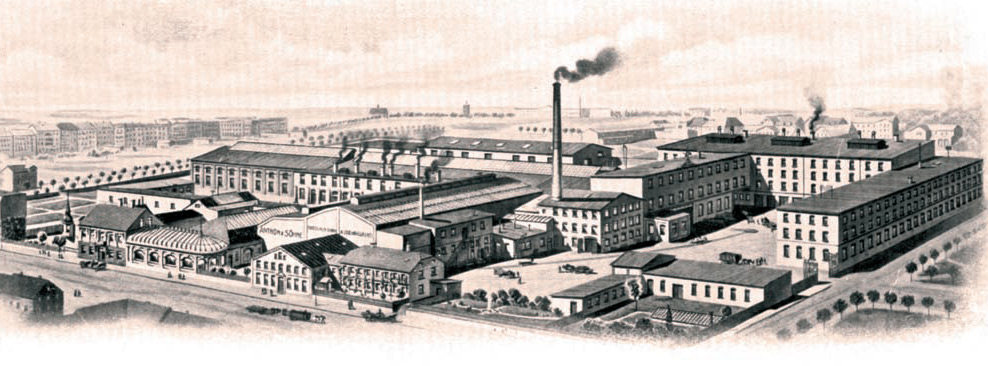

3 November 2015German sawing system manufacturer Anthon, of Flensburg, is celebrating 150 years in business in 2015. We look at where the company has come from and where it is headed.

Since 1865, the company known simply as Anthon claims to have been dedicated to technological progress.

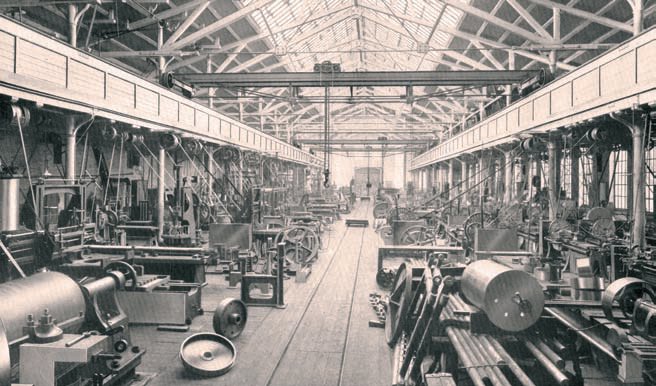

At the beginning of its 150-year history, the team, led by company founder Wilhelm Anthon and his sons, produced furnaces which they developed inhouse, as well as cast iron parts for the region, in their mechanical workshop.

A few decades later, this inhouse engineering company developed sawing, sanding and barrel making machines which were in demand not only in Europe, but also in the US, South America and later even Australia.

There followed custom-made products for customers all over the world, as well as computer-aided production lines for all the various panel types. From wood and building materials to non-ferrous metals, to high-gloss-lacquered particleboard and honeycomb panels.

Since 2000, Anthon has acted increasingly as a general contractor, integrating the production steps of other manufacturers in its own production machinery. The result: complex, high-tech production lines, says Anthon, and the beginning of 'Anthon 4.0'.

Nowadays, Anthon says it develops and builds machine lines that can do much more in addition to the basic function of sawing, feeding or de-stacking.

Besides the specific special constructions of individual components in order to optimise performance, since 2005, Anthon lines have ben primarily characterised by their communication with the different IT systems employed by customers.

Whether SQL database or the ERP system from SAP, Anthon says its lines identify information and provide feedback, which ensures both the quality of the product and the quality of the production process. So, for example, the operator of an Anthon system is visually informed via a screen, or acoustically over headphones, as to how long a saw blade has been in use and in which forecast period he should replace the blade if he wants to get all the panels in the stack sawn to the same quality.

This is made possible by a dynamic team, which the Anthon ceo Ove Lange and his father, Klaus Lange, have gathered around them.

"The Anthon company survives on dedicated, smart people who want to make a difference because machines - no matter how high technology they are - still need people who invent and promote them on the market. Our team does just that. With commitment and looking into the future," explains Ove Lange, who is in fact ceo of the second generation.

For over 10 years he ran the business with his father, who took over the machine factory in 1979 from the Anthon family, and has since developed the company further to make it into the business it is today: an internationally- operating family business with solid solutions for an increasingly digital world.

Counting the generations across the families, then Ove Lange is the sixth generation of Anthon ceo. And, like his father, he shares more than a sense of family with Anthon. In particular, the interest in new technological ways, and the enjoyment of teamwork, whether with his employees or his customers drive him.

" If you want to develop something new, you need ideas, courage and energy. This applies in special machine engineering for each individual contract and that makes the developments so special," said Ove Lange.

One of the company's latest developments is a machine line for Germany. Here, Anthon utilises something which is already known in the book industry: The manufacture of individual products in very small numbers; fast and uncomplicated. Production is carried out after the order is placed by the end customer - in other words, on demand.

"Breaking new ground, for us, is thinking on behalf of our clients. If they want to move away from high-volume towards more individual production, then we make it technically possible," continued Mr Lange.

And so it happens that 150 years after founding the company in Flensburg, he says that a team of 135 employees invents and manufactures machine lines that help customers to be successful in what is becoming an increasingly digital and networked world.