Monitoring the air in our environment

9 March 2012Formaldehyde is a chemical widely used to manufacture building materials and various household products. It is also a naturally occurring chemical in all living things, plant and animal, and is essential to life. However, as with many things, it is concentration which is important and we know that high concentrations of formaldehyde can be damaging to health.

The resins traditionally employed in the wood panel industry are urea formaldehyde (UF), melamine formaldehyde (MF), melamine urea formaldehyde (MUF) and phenol formaldehyde; UF resins are the most widely used.

Wood based panels can emit small amounts of formaldehyde to the air and each panel type has a product standard governing the testing and certification of that product for formaldehyde emissions.

Both particleboard and MDF generally use urea formaldehyde (UF) resins, which emit small amounts of formaldehyde.

Decorative plywood and veneered composites using UF or MF resins are used for interior applications such as panelling, cabinets or furniture.

Anyone involved in the manufacture of any of these products could be exposed to formaldehyde in the air.

In structural panels such as OSB and plywood, exterior grade phenol formaldehyde (PF) and isocyanate (MDI) resins are used; the amount of formaldehyde emitted from PF bonded panels is considered very small, while MDI resins are formaldehyde-free.

Unless due care and attention is paid, formaldehyde emissions from production of those other panels can reach dangerous levels at production lines, especially in areas such as resin preparation and use, forming and hot pressing.

Ventilation in these facilities must therefore be good; it is advised to sample airborne levels of formaldehyde regularly to ensure workers aren’t at risk of over-exposure.

For finished panels, formaldehyde release is highest in newly manufactured pressed wood products and decreases over time. Experiments have demonstrated that in a stable environment (temperature and humidity) formaldehyde release does decrease over time and the low initial values of typical particleboard and MDF panels will decrease by at least 50% within a few weeks of manufacture.

Formaldehyde can be released as a vapour, due to off-gassing from products containing formaldehyde based resins. Conditions of high humidity, heating or agitation (including sawing or grinding) of formaldehyde based products can lead to increased levels of formaldehyde in the air.

Workers may be exposed by breathing in the fumes from formaldehyde products as a result of off-gassing from unsealed or freshly cut surfaces and the associated dust particles.

Exposure levels

In the UK, formaldehyde has been assigned a Maximum Exposure Limit (MEL) of two parts per million (ppm).

In the US, the Occupational Safety and Health Administration (OSHA) has set a permissible exposure level of 0.75ppm.

In Sweden and Germany the maximum permissible indoor level is 0.1ppm. Many other nations have similar exposure level regulations in place.

Safety and Detection

In buildings and facilities where wood based panels are manufactured, it is important that formaldehyde levels are regularly monitored.

In order to ensure employees are not exposed to dangerous concentrations of formaldehyde in the air, it is advisable to detect and monitor levels with a suitable detection instrument.

Real-time results mean that potential over-exposures can be identified as they occur, without the delay of laboratory analysis. If a dangerous level is detected, employees can be evacuated until the risk is reduced.

“Over-exposure to airborne formaldehyde is dangerous to health, but the risks can be substantially reduced if levels are regularly measured and monitored,says PPM Technology’s managing director, John B Jones.

PPM Technology says it has significant experience in the design and development of instruments for accurate detection and measurement of formaldehyde.

The company’s Formaldemeter range of instruments has been in existence for over 10 years and it says it continuously develops and improves them to achieve better performance and features.

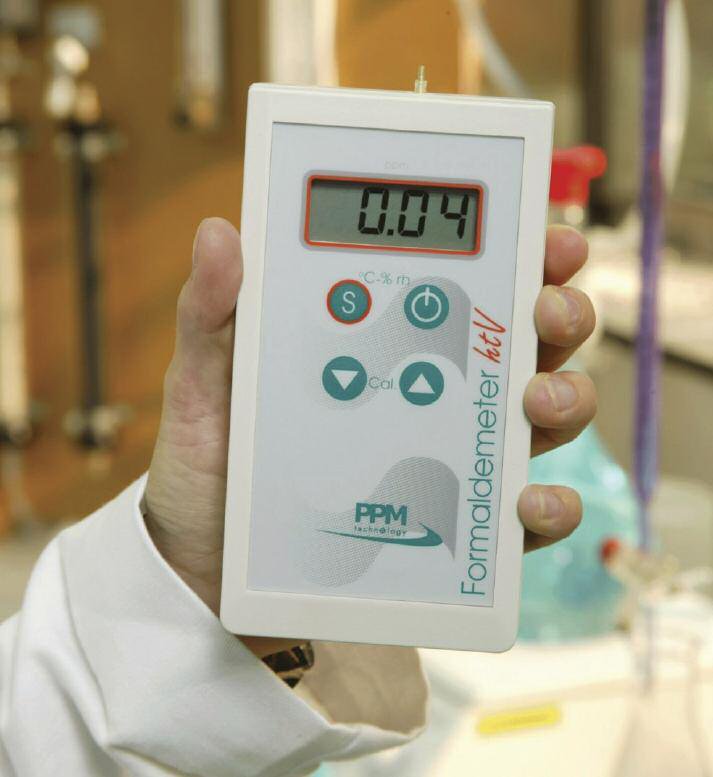

The latest instruments offered are the Formaldemeter htV-m and htV.

“The Formaldemeter htV-m is able to accurately detect and monitor formaldehyde, temperature and humidity in real time,explains Mr Jones. “It can be used as a manual, hand-held instrument or as a continuous monitoring device capable of up to one month of data-logging.”

“The htV-m can precisely measure formaldehyde concentrations in parts per million (ppm) and mg/m3 over a wide range of temperature and humidity, while the built-in memory and real time clock enable the htV-m to log all three parameters and corresponding times, allowing improved monitoring and analysis opportunities.

“The Formaldemeter htV is also a manual, hand-held, instrument, which can take instantaneous single-point measurements of formaldehyde, temperature and humidity.”

Standard hand-held formaldehyde detectors from PPM Technology measure in the range of 0-10ppm. It is also possible for the user to change the settings and monitor for much higher concentrations of formaldehyde, up to approximately 90ppm, says the company.