Harnessing the power of spectroscopy

22 January 2024Dr Morwenna Spear FIMMM, of the BioComposites Centre, examines the use of FTIR spectroscopy to identify glues, binders and coatings used in panel products

From time to time, I get asked to identify the glues or binders in different panels, or perhaps to find out what paint or varnish has been used to coat a piece of timber. This is a job for FTIR spectroscopy. So, what is it…?

The FT part of the name refers to Fourier Transform, that’s the maths that’s used to handle the spectral data. The IR part of the name stands for Infra-Red, the wavelengths of light just above red on the electromagnetic spectrum. That’s with a slightly longer wavelength than the visible light we see, but shorter than radio and microwaves. The infra-red wavelengths are really useful because they interact with the covalent bonds inside organic molecules – causing bending or stretching or other movements in different functional groups. The tiny amount of IR light that is absorbed by the molecule can be detected by the instrument and a spectrum of these absorptions is produced, giving clues to the identity of the chemical being tested.

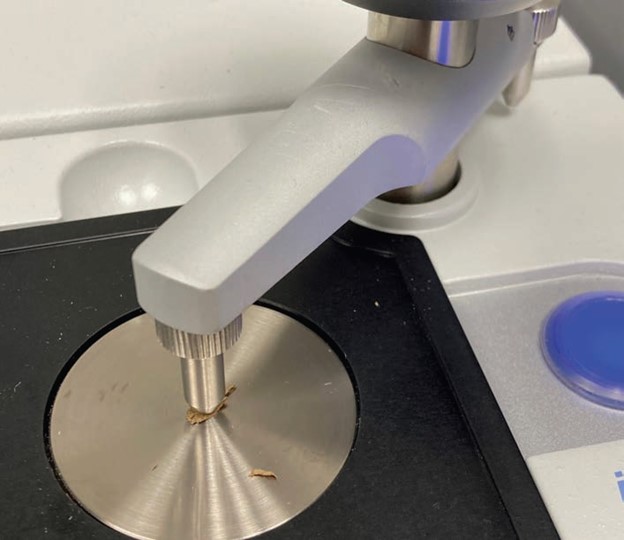

Back when I started, using FTIR sample preparation was a slow business – needing precise sampling of material, milling to a fine powder and then mixing with a salt that shows no absorption in the range of wavelengths before pressing a pellet or a window that could be loaded into the machine. These days a newer method of optics has been developed that lets the whole surface of the sample be presented to a small crystal window and the light interacts with the first few nanometres of the surface. This has sped up analysis of glues in wood panels considerably! Other improvements in optics mean that we now have a highpowered microscope attached to our FTIR spectrometer, so we can analyse particles distributed across a surface, or resin spots, waxes and other additives on wood, getting an image with the IR data for each pixel.

Back to the story. Why would people want to know what glue they’ve got? Well, one of the key reasons is to check the panel is the grade that it claims to be. As we know, adhesives such as urea formaldehyde may have very poor resistance to moisture. So UF resins would only be expected in interior grades of plywood or particleboard. But this doesn’t stop unscrupulous manufacturers from trying to make the bond look a bit darker, maybe adding some colouring agent, to try to appear to be a phenolic resin instead. Or perhaps it’s not through any attempt to deceive. Perhaps a panel gets used in the wrong place by a builder or DIY enthusiast who doesn’t check the grade stamp for the use class. Sometimes it is useful to check whether the panel that failed in service had the right glue in the first place.

Anyway, getting the spectrum is easy, and these days so is getting the answer. Spectral libraries of thousands of chemicals exist. These often include well know compounds, polymers, paints, glues or other commercial products. A search of the library can give a match to the chemical or polymer. Even when there is a mix of compounds present, a little detective work, some spectral maths and logical analysis of the peaks present can give a clear idea of what has been used.

So, next time you are wanting to check you’re getting the product you think you are paying for, remember, there are plenty of analytical techniques that can help you check!