Egger Commits to US Market

29 January 2021The internationally-operating Egger Group is headquartered in the beautiful Tyrol region of Austria. Until recently, it only manufactured particleboard and MDF in Europe and Argentina, but now has a greenfield factory in the US, which began production in September 2020, reports WBPI consultant editor Mike Botting

Egger’s plans for a brand new particleboard production line and two TFL (Thermally-Fused Laminate) laminating lines on a greenfield site in Lexington, North Carolina were first announced in 2017.

The company acquired the 240-acre site in Davidson County and established Egger Wood Products LLC as the company’s US subsidiary.

The site is part of Davidson County’s Interstate 85 Corporate Centre, with Egger as the anchor. Egger moved its existing US sales office from Atlanta, Georgia, to Lexington in 2017, while at the same time opening a warehouse in Livonia, Michigan.

Lexington represents the 20th factory worldwide for the Egger group, with 18 of them being on the continent of Europe.

So why did Egger decide to make this investment in the US and why at this time and in this location?

“The investment in this facility provides the opportunity to greatly expand our presence in the market, serving our customers with shorter lead times,” said Carsten Ritterbach, Plant Manager, Commercial Services. “We are also eager to introduce Egger Innovation here, delivering new ideas, products and services to this market.”

With the decline of the US particleboard industry in recent years (well documented in WBPI’s annual surveys), there was no shortage of mothballed mills which Egger could have bought and regenerated.

However, having viewed several prospective purchases which were not deemed suitable, the company decided to build a brand new plant on a greenfield site.

Which brings us to the second part of my question: Why Lexington?

“We had several options when selecting where we wanted to build our first North American plant,” said Mr Ritterbach, “but it didn’t take long for Lexington to become our top choice. In addition to the great support we received from local elected officials, as well as the community, North Carolina’s historical prominence as a furniture-making hub, the abundant wood-material supply, and the availability of skilled workers, made this area a no-brainer. That’s in addition to a strong transportation infrastructure, proximity to suppliers and customers, wide availability of wood and a business-friendly tax environment. All these reasons make Davidson County the perfect place to do business and a very attractive [proposition] for our first US investment.”

Mr Ritterbach added that the Lexington investment allows Egger to tap into the North American market and to become a significant player in the growing US demand for wood based materials.

“Egger’s goal is to replicate its leading position in the European market and to become the leading brand for wood-based solutions in North America,” he said.

“In line with its corporate strategy, an Egger production facility in North America will further the company’s globalisation and growth. In addition, the investment in the United States will provide market diversification and secure the future for Egger and its employees,” added Mr Ritterbach.

In its only other location outside Europe, Egger has a factory in Argentina, which it purchased from Masisa in 2017, but this was a takeover of an existing plant, not a greenfield development like Lexington.

The laminating and particleboard lines at Lexington were the first phase of a project scheduled to take place in several stages, representing a total investment of some US$700m. This first phase was predicted to cost around US$260m and the designed capacity of the continuous press is 600,000m3 per annum.

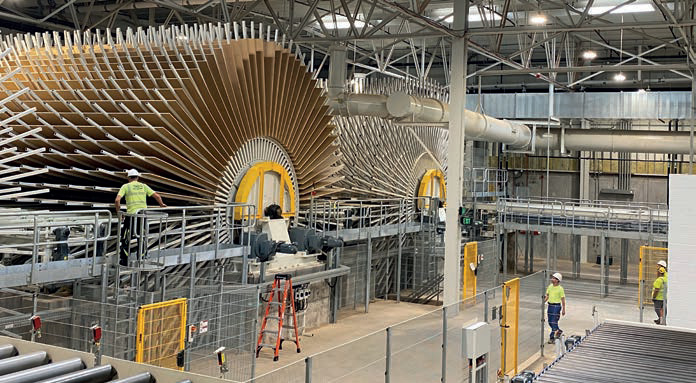

The order for the particleboard production line was placed with German manufacturer Siempelkamp, of Krefeld, Germany.

The ContiRoll continuous press is 10ft wide and 43.7m long and represents the 15th ContiRoll press for the Egger Group.

Siempelkamp subsidiary Pallmann provided the size-reduction equipment, while another subsidiary, Büttner, supplied the the two dryers.

For the supply of the two short-cycle TFL press lines, Egger Lexington chose another respected German manufacturer, Wemhöner of Herford.

Construction began in late-2018 and the ‘topping off’ ceremony was held in July 2019, marking the start of the installation of production equipment.

The first production lines to start up at the Lexington facility were the two short-cycle- press laminating lines. The first board was produced on September 9th, 2020, followed by the first particleboard panel on the 24th of the same month.

The final stages of construction, and the commissioning of the line, could not have come at a worse time, it would seem, in view of the effects of the coronavirus, Covid-19, in 2020.

“The health and safety of our employees, customers, suppliers and partners has remained our top priority throughout the pandemic,” said Mr Ritterbach. “We have implemented safety protocols, such as social distancing and the wearing of masks, and there have been no significant impacts on the construction and commissioning of the plant.

“We’re very thankful that despite minor setbacks in construction due to the ongoing COVID-19 pandemic, our production timeline remained unchanged.

Asked whether the pandemic had significantly affected the availability for work of Egger’s staff, Mr Ritterbach said: “No, although we have had to pivot and work remotely for some team members in certain situations, this has not significantly affected staff availability.”

What about Egger’s customer base?

“Needless to say, the pandemic has affected every business in some way this year and while early lockdowns certainly created some impact, we have fortunately seen that the construction and furniture industries [Egger’s main client base] have been less affected by the pandemic than other sectors. In fact, as people are at home more, many consumers are investing in new furniture, or undertaking renovations. We’ve also found new ways to work with our customers, virtually, to support them. For example, in Lexington we have installed green room technology that allows us to present to customers virtually and to provide presentations introducing the first Egger Decorative Collection.

However, the decision to build the Lexington facility pre-dated the arrival of Covid-19, so why did Egger decide in 2017 to make this investment, I asked Mr Ritterbach?

“We are well aware of the history of the furniture industry in North Carolina and want to contribute to the industry’s revitalisation in the state. North Carolina’s historical prominence as a furniture making hub, its wood material supply, and the availability of a skilled labour force are excellent advantages for our first entry into the US market,” he said.

The TFL lines at Lexington are not yet common in North America, but Mr Ritterbach is confident enough in its future to predict that about 30% of particleboard production will be laminated in the first phase, growing to 60% in the coming years.

“With the competitive advantages of this product, we see eager adoption of TFL by fabricators, architects and designers, resulting in increasing demand from our customers,” said the plant manager for commercial services.

In October, Egger says it launched its first Egger Decorative Collection for North America, designed specifically for the wants and needs of that market. The collection includes 80 TFL decors that will be produced in Lexington, all available with matching laminates and edgebanding.

Egger’s TFL range features 26 white and solid colours, five material and 32 woodgrain reproductions, plus 17 premium Feelwood decors, which feature deep, embossed-in-register (EIR) textures. It offers nine such textures: four woodgrain/material reproductions; three EIR Feelwood textures; and two neutral textures.

The company says it will also stock 16 PerfectSense products, its premium range of high-gloss or ultra-matt lacquered MDF boards, produced at its Brilon plant in Germany. Matching edgebanding and laminates are also available for all PerfectSense products.

Looking to the future, Mr Ritterbach said: “The Lexington investment is a three-phase, 15-year, development. Later phases are, of course, subject to economic feasibility, but our plans for the second phase, beginning in 2025, will involve an estimated investment of US$100m and 120 jobs for finishing lines and added-value production.

“In Phase 3, beginning in 2030, we plan to add a second particleboard production line, with an estimated US$300m investment that will create approximately 250 new jobs. Egger is not the only foreign company to build new particleboard production capacity in the US.

On October 9th, 2019, Kronospan started up a new particleboard line at its panel complex in Eastabooga, Oxford County, Alabama, to include: Two laminate flooring and decorative paper impregnation lines; a particleboard and thermally-fused laminate line; an enlargement of the KronoChem resin plant; and development of a furniture cluster. The particleboard line has a rated capacity of 550,000m3 per year.

Meanwhile, also in 2019, Chilean panel maker Arauco started up a Dieffenbacher CPS continuous particleboard line at Grayling Michigan, with a capacity of 800,000m3 per year, making it the largest line on the continent.

This influx of investors with new, efficient, lines is likely to accelerate the closures WBPI has already recorded of some of the smaller, less efficient, older, particleboard lines in the US.

However, for Egger, looking at the US market going forward the mood is one of great optimism for sales of its raw particleboard and laminated products from its state-of-the-art Lexington line.