Sensor data is fuel for the future

29 January 2021Dr Athanasios Dimitriou, materials scientists at The BioComposites Centre, Bangor University explains how sensors are providing data with incredible accuracy to gain insight into industrial processes

It is true that our lives have been fundamentally changed since the mid-20th century. Technology has reached to a point that today we take for granted technology in our daily life the things we used to consider to be science fiction back in the 1980s. Computers that could send people to space in 1950s are now so much inferior compared to our standard smart phones.

We use artificial intelligence (AI) to assist us in our daily lives; we have face and speech recognition, video calls, GPS interactive maps and the list extends to endless capabilities and new developments. And all of these can fit in a single device that can fit in our pockets. It is mind blowing to consider the possibilities that all these new technologies can offer. Technology has become more and more approachable, to the point that anyone can build an interactive robot as a hobby!

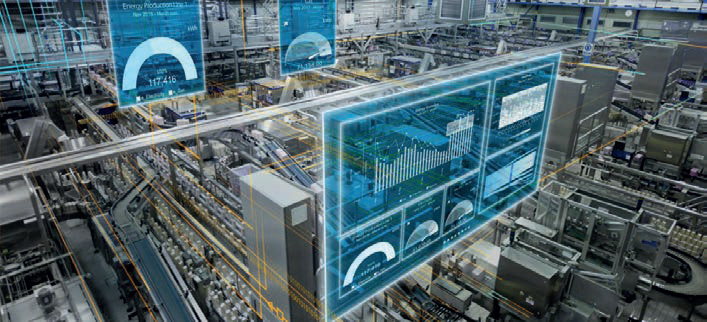

This impressive advancement of hardware, computer power and reduction of cost and size of electronics, in combination with AI and machine learning, have pushed our technological boundaries in industry as well.

The development of a vast array of new sensors has helped the generation of big data, and with the help of machine learning, we can use this to generate models that can speed up or even replace the prototyping process. We can also monitor manufacturing processes and product performance with incredible accuracy. Here we think about uses in the wood panels industries.

From regression models to cluster analysis many new prediction capabilities have been used extremely accurately for in-situ production monitoring. We can now use data to train our models, not relying on the necessary understanding of the used data or their correlation in the models. Artificial Intelligence (AI) and machine learning have replaced a part of human perception and can now exceed our ability for data analysis.

Machine learning can overcome our failure to see correlations in complex data sets, leading to a massive improvement in the value of general data. For example, data from Fourier transform infrared spectroscopy can now provide very precise predictions on panels performance and attributes.

Near Infrared (NIR) spectroscopy can also be used in-situ in the wood-based panels production, and regression models derived from Principal Component Analysis (PCA) and Partial Least Square (PLS) regression of this data can provide very accurately predicted information on attributes from the resin reactivity, to free formaldehyde content and mechanical properties such as internal bonding (IB) strength, modulus of rupture (MOR) and modulus of elasticity (MOE).

Multivariate regressions and artificial neural networks (ANNs) have been used to predict plywood MOR and MOE as an in-factory quality control tool. Similarly, ANNs have also been used as a tool to investigate the influence of particleboard physical properties (moisture content, water swelling, density and thickness) to the IB strength with no statistical difference from the experimental data. Tool wear prediction has also been modeled using modeling methods like artificial neutral network, back-propagation neural network, genetic algorithm, linear filtering, Gaussian mixture regression etc. and inexpensive sensors mounted on the cutting equipment detecting vibration, sound, force, temperature, etc. Tool wear models have also been made using laser and vision-based monitoring equipment. Hyperspectral cameras and regression models can be used for wood species identification in order to make it easier to spot illegal logging in log yards and transportation hubs.

Product performance and in-service can also be modeled using machine learning and regression models. Mechanical and physical properties of wood-based materials in high humidity environments like attics have been modeled with NIR. Simulation decision support tools can also assist to identify the optimum solutions to complex and interrelated issues that will improve productivity. Today we can train our models with data that we previously would not have had the computer power for, as processing power has increased and complex computations can be achieved with relatively low-cost computers. The price of the electronics and sensors has been reduced significantly so big data can be easily produced and be analyzed with no need for supercomputers.

Does technology outpace our learning capacity to understand the world around us? Maybe, maybe not... One thing is certain, the capabilities of these tools are endless – finding new correlations between the properties of our products using this new data in order to produce more and better models for further process optimization.