Interzum wows with cutting-edge designs

26 July 2011In recent years, Interzum has suffered some strong competition for its once-totally dominant global position among furniture/interior decoration exhibitions. At times, it even appeared that it just might lose that position. However, the organisers, Koelnmesse, went on the offensive with initiatives such as the successful creation of Interzum Guangzhou and Interzum Moscow and some significant changes to the way the Cologne show was structured, improving the experience for both visitors and exhibitors.

That thrust, and the loyal support of its long-term supporters, seems to have been enough not only to re-emphasise this show?’s unique offering but to give it almost a new lease of life and to firmly re- establish it as the leading show in its sector.

Exhibitors’ reactions to this year’s biennial Interzum show were very positive and the figures released by Koelnmesse back this up.

Visitor numbers were up 13% on 2009, while the international content of those visitors increased by 24%.

Those extra visitors also had a greater number of exhibitors to visit than two years ago, with 1,434 companies taking booths at the show (up almost 6% on 2009).

It is worth noting that only 378 of those exhibitors came from Germany.

Of course the global recession took its toll to some extent on the 2007, and more so the 2009, shows and it was pleasing to sense a new mood of optimism at this year’s event. The fact that host country Germany appears to be leading the way out of that recession must have helped.

From WBPI’s point of view, everybody who is anybody in the decorative surfaces supply chain was present with a booth. This runs from paper and foil makers to printers to press plate makers. The latter group have enabled decorative surfaces to literally enter a new dimension with in-register embossing bringing the printed papers to life. Whilst not exactly a new technology, these accurately textured plates have improved by leaps and bounds since their introduction.

By working together, plate makers and printers have elevated decorative foils and papers from average imitations of the real thing to surfaces which even experts have to examine very closely.

A pioneer in in-register embossing and other equally important developments to surfaces was press plate maker Sesa of Italy and this year’s Interzum saw the launch of its Super-high Gloss range.

“Mirror-quality surfaces are a hot topic in low-pressure laminate (LPL) for cabinetry worldwide,said Sesa’s Brian Jones.

The new range offers three levels of mirror quality: Mirror 8 CR, ND, CR Plus and NCR in descending order of high gloss.

“Gloss is a product of the plate, the decor, the resin and the base board,said Mr Jones. “We help the customer figure out the system he should use for maximum gloss and clarity.

“We offer our exclusive resin consultant service within our offering to the customer to consult on this technology.”

Sesa began a 50/50 joint venture company in India, Sesa MSF, in 2000 and that business is now 75% owned by the Italian company and by the end of this year or the beginning of next, the renamed Sesa India (in May 2011) will be offering chemically etched plates rather than just refurbishment services.

Sesa has also changed from offering “press platesto “press moulds”, defining itself as a “surfaces specialist”.

It also launched its completely revamped website in May (www.sesaplates.com), where visitors can see all its surfaces, and is nearing the launch of an “isesa appfor iPads as a sales tool for its own personnel in which customers can see the effect of changing light incidence on finishes by tilting the iPad.

Another press plate maker, headquartered in North Carolina in the US, has “gained a lot of traction in North America”, according to Kings Mountain International’s (KMI) sales executive Gary O’Neill, and is rapidly building on this sound basis to increasingly become a player in the global market.

“Flooring has been a major driver in North America, with improved production technology and printing demanding ever-better quality press plates which we at Kings Mountain provide,said Mr O’Neill.

KMI offers mirror and matte plates as well as in-register-embossed designs. It offers chemically and mechanically etched plates and will re-gloss and refurbish used plates.

Under the title “SteelArt”, Sandvik Surface Solutions offered its range of designs in press plates, as well as in endless steel belts for continuous laminating presses: “It is a science and an art,says the company.

As well as its design services, Sandvik Surface Solutions offers smooth, textured, polished, high-gloss-polished, matte or super-matte surface finishes, as well as services such as cleaning, refurbishing/gloss level adjustment, de-chroming and new hard chrome plating, re-texturing, mechanical repair and service training for customers’ engineers.

Hueck Rheinische of Germany (part of Berndorf Band of Austria) offers smooth and textured press plates and endless press belts and displayed its range of surfaces on its booth at Interzum.

The company displayed a full range of surfaces from gloss to matte and textured and also offered its press compensation pads.

Interzum is an event that all decor printers really have to attend and they were certainly there in force this year.

Schattdecor, one of the best known names in the field, had a large booth presenting its considerable range of decors in themed areas.

The company offered what it called a “new dimensionin decors.

First of these was Santana Oak with fine pore structure and attractive detailing such as tiny knots and long cathedrals for a rustic look.

Wyoming Maple offered a fine fibrous texture with clearly delineated planking with an equal mix of straight and figured grains.

Amargnac Elm showed subtle pores and tight growth lines to give a mainly straight-grained look, while Sonoma Oak had negative pores and square-cut saw marks as well as typical oak markings.

Schattdecor also exhibited its digitalVISIONS range of inkjet decor prints.

Impress had a very impressive stand which looked rather like a designer house with glass walls. It took two weeks to construct in the Cologne Messe hall.

The company offered its “Seven Citiesdesign collection, offering a wide range of designs in natural wood and other effects.

Impress also promoted its melamine-substitute resin made from sugar. As melamine resin comes basically from fossil materials, the sugar-based substitute is seen as an environmentally positive solution. The company claims that this new resin substitutes three truckloads of melamine per month, equivalent to an annual quantity of 700 tons of melamine replaced. Local availability of the sugar-based raw material also saves on transport miles, says the company.

The new resin system is said to be usable in all the normal ways for short-cycle lamination and is scratch-resistant and robust in paper laminate surfaces for worktops.

Homapal offers a range of laminates which are all made from real wood and real metal rather than melamine paper alternatives.

The company won the Intelligent Material and Design Interzum Award for 2011.

Interprint showed its new collection at Design Post Köln (Cologne) and used the slogan “Combinationsfor its wood and stone decors in combination with single-colour metallics as well as surfaces with tactile effects. The samples were arranged on white walls as ‘works of art’.

“Visitors are impressed with how these surfaces, colours and structures work in different combinations,said Salvatore Figliuzzi, head of marketing and decor development at Interprint.

Interprint’s elm tree decor, Swiss Elm, was the centre of attention.

German decor printer Süddekor had an impressive stand where its entire 2D Group presented decorative surface innovations. Structured finishes on flooring and furniture surfaces were a focal point, together with in-register-embossed surfaces and real pores for finish foils.

The outcome of ‘Perfect Profile’ laser engraving was also shown.

The group, together with its Süddekor Art division, unveiled new decors printed with the use of laser-engraved cylinders to give high-definition decor images.

The stand combined beautifully the extensive use of green live plants with the high-tech of digital imaging.

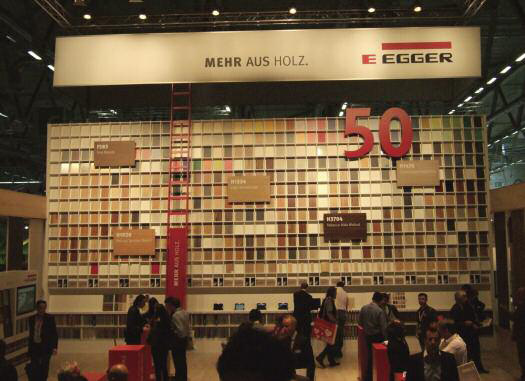

Panel manufacturer Egger, headquartered in Austria but with an international spread of mills and a strong presence in decors, celebrated its 50th anniversary, having been founded in St Johann in the Tyrol region of Austria in 1961.

Egger’s booth concept was not simply to show off decors and materials but to offer ‘solutions’ to its visitors. The booth featured a high wall of decor samples and a truck which travels around as a mobile showroom for everything the company has to offer. This includes MDF, particleboard and OSB panels as well as that vast range of decors, but importantly these days, it also includes Egger’s lightweight panels.

Egger’s colours and textures are trending to an increasingly natural and real look, combining design and nature in its 2011 collection.

The company says that in addition to individual decor consulting and visualisation in the Virtual Design Studio, digital printing is a key component of the overall package of digital solutions which it offers.

Roma Plastik AS of Turkey was bought by Egger in 2010 and produces a range of edging decors to match surface decors precisely and offered 40 new decors at the show. In fact it claims to be the third largest supplier of edging worldwide.

Moving away from surfaces and decors, we visit Hettich, a supplier of hardware for furniture and interiors. The company says it is particularly strong in the field of specialised fittings for lightweight panels, particularly hollow-cored panels.