Sunds gets dry

7 April 2009The market has long been looking for a system tosignificantly reduce resinconsumption in the production of such products as low density, mediumdensity and high densityfibreboard. Sunds MDF Technologies AB in Sweden claims to have the answer

When dry fibreboard technology was first developed, typical particleboard methods of resin application were used. The performance of these early systems was not optimal and when blowline blending was introduced at the end of the 1970s, most of the producers changed to this system.

Blowline blending solved the problems associated with frequent cleaning and maintenance stops but the heat from the dryer reduces resin reactivity, resulting in increased resin consumption. The addition of resin in the blowline also creates higher levels of formaldehyde in the dryer exhaust.

Attempts to apply the resin on the dry side were renewed some years ago but the systems still had the past drawbacks of resin spots and frequent maintenance stops for cleaning. Moreover, the saving achieved was limited. In response to the growing need to reduce resin consumption, cut costs and minimise formaldehyde emission, Sunds MDF Technologies (a member of the Dieffenbacher group) developed its EVOjet dry resin blending system.

The first EVOjet system delivered by Sunds MDF Technologies has been in operation at Flakeboard’s fibreboard mill in St Stephen, New Brunswick, Canada, for more than two years. The operational objectives set for this system have been achieved, says Thomas Olofsson, Managing Director of Sunds. Significant results are reported, particularly in resin consumption, pressing capacity and emission levels.

The revolutionary dry blending system was developed in cooperation with Flakeboard, the largest producer of composite wood panels in North America.

The operating principle of the EVOjet system is based on a new dry-resinating method, in which all resin is added after the dryer. The only additive introduced prior to the dryer is paraffin wax.

Unique resinator

The EVOjet system is said to ensure perfect resination with a combination of large surface area of fibres in the conveying air and effective resin distribution.

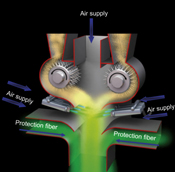

The heart of the EVOjet system is the resinator featuring two high-speed rotating spike rollers which effectively disintegrate the fibre flow. Any fibre balls or flocculates are divided into single fibres. The fibre is distributed over the width of the spike rollers and the flow is accelerated by the high-speed rollers. The disintegrated flow of fibres is exposed to the resin from three directions. With a 25 tonne per hour (t/hr) fibre throughput capacity, the exposed fibre flow surface is about 320m2/second.

The EVOjet resin nozzles tailored for this application atomize the resin to <15 micron droplet size. The surface area of one litre of resin is more than 400m2.

The EVOjet dry blending system is design to allow 100% addition of resin on the dry side.

The unique design of the resinator combined with the resin nozzles ensures a better resin distribution than any other available dry resin system on the market, claims Mr Olofsson.

Automatic cleaning

The resin nozzles are mounted on moveable bars to facilitate an automatic cleaning sequence without any production interruption. Protection fibre is added just after the resinator to avoid any build-ups in following pneumatic systems. Additionally, the early sections of the system are protected with non-stick material.

The EVOjet system is available in four different sizes to cover the typical MDF capacity range. The largest EVOjet system is designed for a 36t/hr fibre throughput in a single unit.

The modular design makes it possible to retrofit the EVOjet into any existing line. The feeding of the EVOjet can be carried out pneumatically, which makes it easier to overcome any layout constraint that is often encountered in an existing plant, claims Sunds.

Significant results

According to Flakeboard St Stephens, the resin consumption has decreased by nearly 50%, while product output has increased by 15%.

The press line capacity increased by 15%, due to the ability to use a © p64 ß p63 higher moisture level on the press line without the risk of blisters. The amount of reject panel has remained at a very low level, says the panel maker.

The formaldehyde emission tests conducted in the dryer, dry blending system and press show that the overall emission levels are lower compared with blowline blending, says Mr Olofsson. The emission reduction from the dryer is 90% compared with conventional blowline blending, which is significant, he adds.

The results were reached without compromising the panel properties, production uptime or panel surface quality, claims the managing director.

New installations

Two more systems are now in production: one in Flakeboard’s mill in Eugene, Oregon, in the US; and one at Daiken in Bintulu, West Malaysia. The two new systems have been in operation since the beginning of the year.

The EVOjet system at the Malaysian Daiken mill is designed for 15t/hr of fibre throughput. According to Daiken’s spokesman Edward Lim: “The EVOjet was chosen based on its performance, particularly the substantial resin savings, without resin spots on the panel, compared with older generations of dry-resinating systems”.

Flakeboard has commissioned its second EVOjet system for its MDF plant in Eugene, Oregon. The system is designed for up to 19t/hr of fibre throughput using both MDI and UF resins. The EVOjet is installed as part of the plant’s control equipment to comply with the environmental regulations in Oregon.

Sean Coffey, Plant Manager at Eugene MDF, states that: “The start up of the EVOjet was extremely smooth, with only one week tuning, operating the system on the day-shift. Thereafter, the system has been in continuous operation yielding the targeted savings”.

Recent Eugene results

The verified resin saving at Flakeboard Eugene exceeds 40% at retained board properties and, most importantly, the panels are spot free, says Sunds.

For certain grades, the improved panel properties at the reduced resin levels have allowed a reduction in panel density.

Furthermore, the EVOjet resinated fibre is said to have improved the mat consolidation after the pre-press. This comes from increased tack of the fibre on the press line. The mat strength is considerably higher and the mat reaching the press is more compact, it is claimed. The improved mat in Eugene is also said to have resulted in less pre-cure in the panels. However, the main advantage in a continuous press line is the possibility to operate at higher line speeds, says Mr Olofsson.

New projects

Flakeboard has ordered its third EVOjet system for the MDF production line in St Stephens. Installation is scheduled for autumn 2009. The EVOjet is designed for a capacity of 15t/hr.

This will be the fifth EVOjet unit engineered and delivered by Sunds MDF Technologies. “The EVOjet offers our customers possibilities to substantially cut variable costs in MDF production through the reduction in resin consumption,concludes Thomas Olofsson. “Combined with such other benefits as lower dryer emissions and better fibre mat properties, the EVOjet system has already been well received by the market and we expect more to come.”