Steinemann: Quality and Support come first

6 December 2016Steinemann is based in Switzerland, where manufacturing is expensive but where quality more than outweighs the capital costs

Across the border in Switzerland, at St Gallen on Lake Constance, is Steinemann, the specialist in sanding equipment for the panel industry.

Being Swiss-based, it is of course outside the EU – a position it will soon be sharing with post-Brexit Britain. To UK-based manufacturers wary if not downright scared at the prospect of going it alone and wondering what sort of tariff arrangements they might eventually have to cope with Markus Müller, vice-president and sales and marketing manager of Steinemann, offers some reassurance. "We have a very good relationship with the EU. We don’t see being outside it as a problem. We are in a way an island, cut off from the rest of Europe by mountains and lakes rather than by the English Channel, but cut off more significantly by currency. We sell in euros or sometimes in US Dollars, but we pay our costs in Swiss Francs, so a high Swiss Franc is a definite disadvantage to us in past years of euro-crisis, when either the Swiss Franc was strong or the euro was weak, depending on which way you look at it. But the franc did not move against the dollar, so I suppose you can say it was the euro that had fallen. We could not put our euro prices up so that put a lot of pressure on our margins."

The situation now is healthier. But performing well and healthily and ending up with financial surpluses do not always go together. As this year. Exchange rates were not this time to blame.

"2016 has been a really great year for our company," says Mr Müller. Our people really worked. Our market share went up. We made important improvements in other areas. We greatly improved efficiency in our factory so that production times have come right down and so delivery times have come down as well, and this has helped hugely in the economies of production. Financially though, it was not a great year, although we did achieve every company’s target of staying in the black."

Why, if the company made so strong a showing, did no huge dividends or money in the bank result? The answer lies in the ownership, and in the years ahead. "We made quite a lot of investment to be prepared for the future," says Mr Müller.

"We are family owned, and a family owned company is the best kind. I really do believe that. Such a company can think long term. Shareholders would have demanded the money we invested as dividends. A family owner can say 'I can do with less money this year in order to make more in the future'; the thinking can be not short-term but in generations."

It is very nearly a 100-year-old family firm. The family in question is not Steinemann, though Ulrich Steinemann founded the company as a maker of textile machinery, in 1917 – but the Stuerms, who bought it from Ulrich Steinemann in 1987. Mr Stuerm, a metal trader, had previously supplied raw materials.

Steinemann has been making wide-belt sanders since 1960. By 1988 it was operating globally. The company sells 98% of its products abroad – not too surprising, given Switzerland’s pseudo-island status; "Our only Swiss client in the past year has been Swiss Krono."

Turnover is CF40m (€37m / US$40m) a year. The company has a 10,000m2 production area and 140 employees, 100 of whom, including 10 trainees, are in Switzerland.

"Wide band belt sanding machinery systems for MDF, HDF and particleboard is our strategic area. The reason we are successful is that we have built up in the past a great service network for our customers."

It sounds a cliché, something that every marketing man will say. But Mr Müller can elaborate on that and give it legs.

"Our machines have to give good performance, good quality of output, must run 24/7 without problems. And they do exactly that. They are not cheap machines. But to the customer, the cost per cubic metre of sanded material is overwhelmingly really the cost of sanding belts, which you have to replace almost daily, and of power consumption; the capital cost of the machine itself is trivial in comparison and pays itself off within a year.

So a price difference of US$100,000 on a US$1m machine should not be an issue for our customers. Write that down in a brochure, and no-one will believe you. Show them, on the other hand, and supply them over many years, and people will say 'Yes, I WILL pay that percentage more for a Steinemann machine because I know I will get that money back in reliability, in durability, in servicing and support'. So we MUST support our customers.

This is where we are investing money." And that is why, in Steinemann’s mission statement, the first item is ‘customer focus.’

So once again, tradition, or history, becomes a theme of this series of articles. Steinemann is where it is today because of where it was in the past; and it has every intention of continuing that tradition. It will continue supporting its customers, in the old way and in new ones.

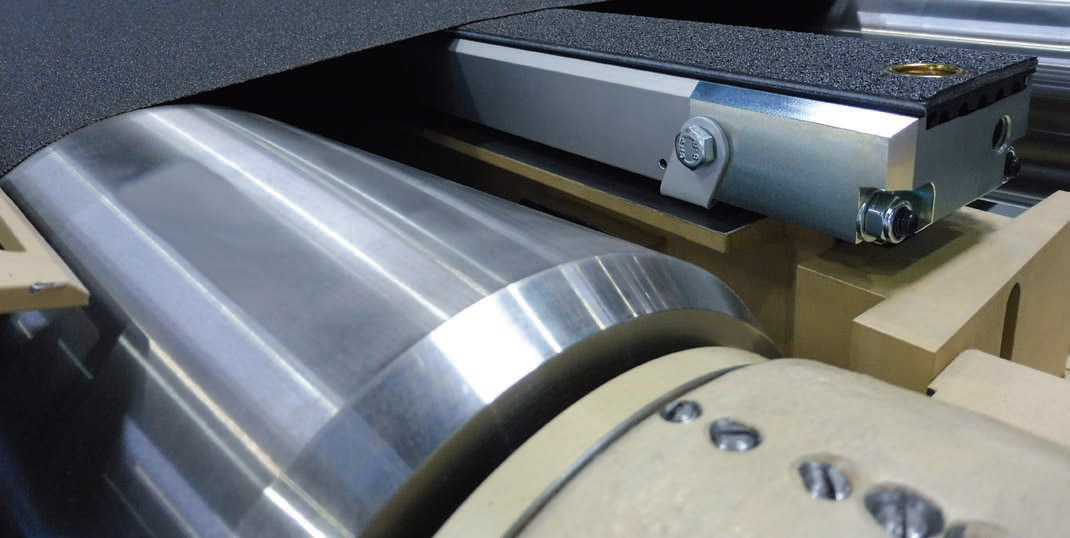

The heart of a sanding machine is the contact drum, the long metal cylinder around which the sanding belt runs. The drum is also Steinemann’s special pride and competence. "We outsource such things as frames for our machines to other producers here in Switzerland; other components we outsource to the eurozone; but the drum is the competence that we will always produce ourselves." Herr Müller shows me them being made. It is done with all the silent precision of an operating theatre. This is after all the nation whose absolute precision in engineering has produced the Swiss watch. The Steinemann drum is produced with similar care.

The quality of the steel it is made from is critical; so too is the welding, the surface grinding, the balance. A single drum can weigh 1.6 tonnes and rotates at around 1200rpm. The slightest imbalance will lead to vibrations and chatter-marks on the sanded board. Tolerances are down to two microns in diameter roundness and five microns in straightness over its length of three metres or more. "Our drums, with the special arctech® coating, can last three years; most drums from our rivals have to be replaced after one year – and these are expensive items. And we can re-furbish and re-grind our used drums for our customers – again a unique service."

Since 1977 Steinemann has sold 5,300 sanding heads to 79 different countries. A board sanding line has several heads, sanding first with coarse grit belts then with progressively finer ones until the desired degree of smoothness is obtained. At between six and 12 sanding heads per production line you can work out how many lines they have supplied, and the answer comes out as ‘most of them.’ In 2005, Steinemann began making sanding belts as well as sanding machinery.

The logic was that a sub-standard belt will give sub-standard results, no matter how good the machine running it may be. ‘A customer would come to us with a board that had chatter marks – ridges, unevenness – on it, and blame our machines.

We would say it was due to the bad belts that he was using; and the belt-makers would say it was down to the machine, and so the only way we could solve the customer’s problem was by taking the whole process into our hands."

As technology improves, the symbiosis between belt and machine, and between other components, becomes even more relevant. "We can optimise design of belts and machines to work better together. We are working on systems that will tell when a bearing might need replacing," says Mr Müller.

"We have an R&D project, supported by the government, on ways to verify the lifetime of a belt. What are the parameters most significant for that? Is it temperature rise, or the power taken by the motor driving it? We like to bring solutions to our customers; and with solutions like that it will become ever easier to supply total surface quality."

As with the other companies we feature, Steinemann has a niche, but an expanding niche. "Our expertise used to be in sanding machinery. Now it is in the whole sanding process, including support, analysis, maintenance.

"We have started to establish the 'Quartz Circle' an exclusive customer loyalty programme. Customers who regularly order spare parts, sanding belts and sprint inserts will get discounts and free service hours.

Another highlight is that we have begun to hold sanding seminars, here in St Gallen, where a customer’s employees can be taught the theory and practice of sanding. No-one else does that.

"We have guys here with expert knowledge of sanding. What we are trying to do is bring their knowledge into an expert system so that we can recommend to any operator what he should do in any situation. What we can offer now is not a sanding machine, it is a smooth surface on boards," concludes Mr Müller.

"Our customer no longer has to worry about how to achieve it. Board makers have enough other things to worry about. We now do the worrying for them.