Schelling cuts straight to industry 4.0

6 December 2016Schelling is the worldwide leader in cut-to-size machines and plants for wood panels

Schelling has been making saws in Austria since 1917. Beam saws are the company's speciality; two-thirds of Schelling’s output is for the wood and panel industry.

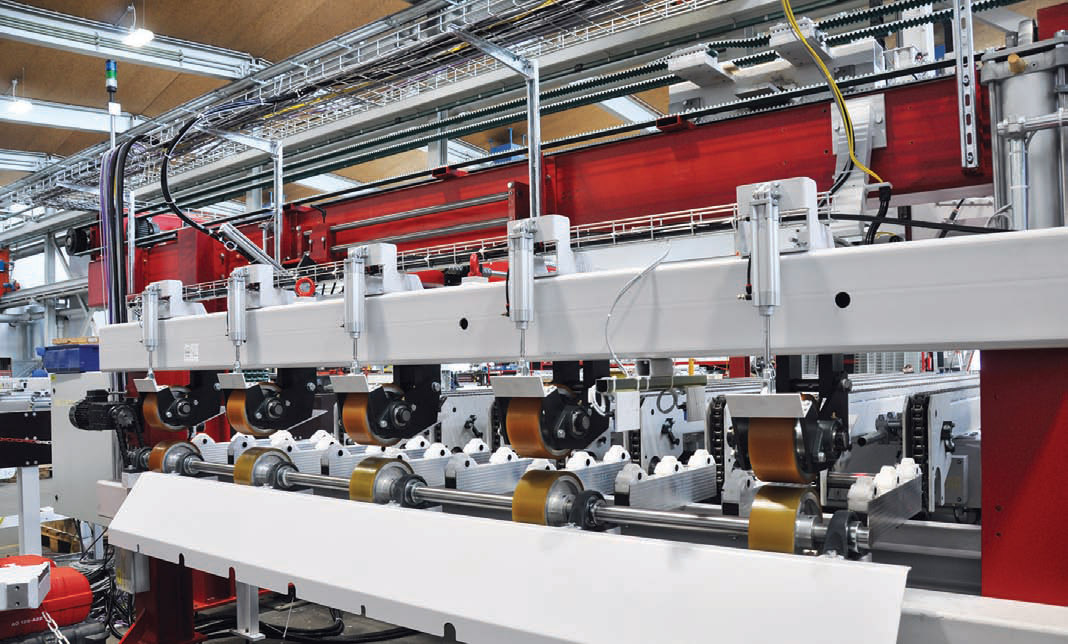

As part of the whole panel cutting process the company builds also the systems that automatically deliver the panels to the blade and stack and pile the cut pieces afterwards.

The promotional video in the factory reception area shows it all in action, and shows it beautifully, a book of boards sliding in and out of the saw, withdrawn, turned, pushed forward again for the next cut, the process repeated until the panels are reduced to the required smaller shapes and sizes and are stacked for onward transport. It is a ballet of boards and machines in motion.

"This is the focus of the future industry," says Wolfgang Rohner, Chief Executive Officer & Managing Director at Schelling. It is also Industry 4.0 in action – joined-up production processes, controlled by sensors and software, the whole system together delivering optimum efficiencies and savings. "We have realised several of these projects now, together with IMA, a company we took over last year."

IMA is a highly regarded specialist for edge processing technology and systems for the furniture and component manufacturing industries. The takeover brought the workforce up to 1,350 people, in Austria, Germany, Poland, Slovakia and elsewhere, and the revenue to over €250m. "We have a global presence. The US is one of our biggest markets. China is another area of growth. Our home market is Europe, not just Austria."

Questioned about the advantages of being Austrian-based, Mr Rohmer once again echoes the ‘quality first’ philosophy. "We make very rigid, very stable machines that last a lifetime. That has always been our goal, and we have not left that street: we sell performance and reliability. That basic of our existence has to be very strong, or we would not survive. And being in Austria gives us qualified and well-trained people."

And it is not saw tables that Schelling sells: it is systems that deliver sawn boards in the dimensions and quantities and stacked in places where they are wanted.

"We have the right people for project management to see that all is running smoothly. We have the after-sales service, we support the customer for life.

"And we see that the market is moving into automation. Robotics, handling and so on are our challenges. We have a fully automated saw for aluminium, no-one has done that before; and we already have automation in wood."

As that video showed. "We see all of that – the saw-bench, the handling machinery, the software – as one system. Our core competence is in cutting but also in everything that you need: feeding units, stacking units; which means we have been able to put Schelling machines in all the big companies.

That in turn gave us a big learning curve: if you do everything, you get the knowledge. A major advantage is that as a mid-sized company we produce everything in-house. We are not the biggest but we are the most experienced, with the highest technology." Or, to put it another way, "Someone has got to be the best, and it might as well be us."

"For the board industry we have new ideas. Since we have experience of handling equipment, pre- and post-sawing, we are providing complete surrounding equipment. We face market diversification; consumers want ten colours now where before they were happy with two; they want 100 different cabinet shapes. It is the customisation effect. It means that board producers who make in volume have got to become flexible. Their biggest problem now is to reduce lot sizes. This we can help them with, via automation.

"Customers order differently now – in smaller quantities, in shorter time-frames, and in more specifications. Now the order might be for just 10 sheets of a particular type, when before it was in thousands.

There is potential for change here. You need flexibility, quick machines, smart handling solutions; you need to offer a system – a solution. There is both push and pull in this change: Our customers are demanding it from us, and we are telling them of the need for it," says Mr Rohmer. "When you know there is a demand you dig a little deeper and you find there is a possibility. Some customers know exactly what they want, while with some we hold discussions and workshops to work out their ideas for the future, short and long term. We develop together.

"It would be easier for us if the customers knew what they wanted to be doing in five years' time – but then if they knew that, they would be doing it now!

"Certainly, cutting single boards rather than books is more the future for the furniture industry. Typical lot sizes now are from one to five. And of course in cutting different shapes from single boards you arrange the shapes like a jigsaw to leave as little wastage as possible – we have automated systems to calculate the best arrangement. If a company takes 10 lorry loads of boards, you don’t want to throw one of those lorry loads in the bin as waste.

The bottom line is: utilise the material. Throw as little as possible away," he says.

"We design our machines with care and imagination. An example is our dust control system. The rotating saw-blade tips, and so the dust they throw off, are moving at 100m/sec; the air current in the dust extractor is moving at 30m/sec. We therefore need to reduce the speed of the fast-moving dust before it enters the slow-moving air stream. We have added hardened-steel friction plates to do that; they have to be hardened steel because the dust would erode normal steel in a matter of days. Dust management is important.

"We are not building a machine to a certain market price," continues Mr Rohmer. "We want to build a good machine. If it can be sold, we sell it. We have many good ideas that we cannot sell; but we have many simple and cheap ideas as well. For example, the sensor by the saw blade tips needs to be kept clean by a current of air.

So we re-direct the current of air from the rotating blade: it is strong enough for that, and it saves laying an airline from a compressor across the factory floor to the saw table. It is little touches like that which make the quality difference overall. Somewhere, the difference is there in our machines," says the CEO.

"There are always some design factors that we keep the same in our small as in our large machines. Physical laws don’t always let you do that. But when we have a good solution that works, we keep it. For instance, we are the only people using flat-bar guidance systems. We have been using them for more than 40 years. It might be old technology but it works, it is reliable, and it keeps its accuracy for the lifetime of the product. But drive systems do change and develop. So we do change drive controls and software. Similarly, testing a machine at the factory is half the price of testing it on site and it decreases installation time, so we do that.

"For the future, we have to keep on working on innovation, performance, reliability. Digitalisation makes new challenges. The internet of things is with us. We already have remote diagnostics – customers can ring us and our technicians here in the factory can log on to their control systems and advise them. These are going to be the changes for machine builders.

We already have future customers who are completely automated. Industry 4.0 is a big world."