Merging technologies

16 December 2014Steel belt and press plate manufacturer Sandvik says its customers are aiming for growth by responding to the changing needs of the wood based panels market.

Sandvik's relationship with the wood based panel industry extends back more than 50 years, to 1957, when the company supplied the first steel belt to be used by the wood industry, for a single-opening intermittent press developed by Bahre & Greten in Springe, Germany.

Since then, the company says it has continued to innovate, producing steel belts for most wood based panel-related processes such as MDF, OSB, particleboard and coated boards, while introducing developments such as chrome-plated steel belts and new high-strength steel grades.

Today, the company says that every supplier of press systems for the wood based panel industry is a Sandvik customer, making use of the company's belts and service support.

Global product manager Jörg Kaufmann said further product innovations would continue to arrive on the market, while the company's level of service would also be of growing importance.

"Looking forward, the ability of our customers to compete against low-cost operators will increasingly depend on them being able to produce high quality products such as MDF and HDF, while at the same time maximising output.

"And as Sandvik steel belts are at the heart of continuous press operations, this will mean us delivering belts to precise tolerances - particularly important on products as thin as 1.8mm - and also delivering the levels of support necessary for them to stay productive.

"Our investment in a worldwide service network, effective maintenance and repair tools, and ongoing technician training programmes means that we're able to deliver just that."

Textured solutions

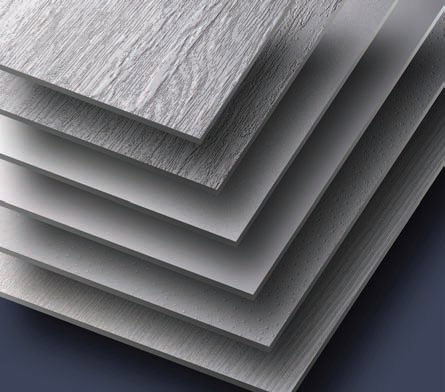

In the German town of Ennepetal, Sandvik manufactures textured press plates and endless press belts for laminates, melamine coated wood based panels and other surfaces.

The company says it the only facility in the world where both products are manufactured under the same roof.

It says laminate surfaces are another area in which differentiation will become increasingly important over the coming years - a reason why Sandvik places great emphasis on quality and design.

Sandvik's design centre allows visiting customers the opportunity to see and feel more than 1,300 textured laboratory plates, as well as assessing samples produced on two laboratory presses.

Design is also the focus of an initiative which commenced in 2013, through which students of industrial design at the local university were encouraged to think "out of the box" and create innovative new surface textures. So successful has this joint cooperation proved that three of the students' designs were subsequently bought by Sandvik and introduced to the industry.

Design and quality are both central to registered embossed surfaces, an area of increasing importance to Sandvik, as the market looks for more sophisticated surfaces for the flooring and furniture industry.

As its name suggests, registered embossing delivers absolute precision matching of surface texture and decor paper in surfacing products, for a far more realistic effect.

As well as working in close cooperation with decor papers, Sandvik has recently announced the successful development of its first in-house registered embossed texture - Vintage Plank - a natural-looking product with the look of driftwood, ideal for vintage flooring surfaces.

Other recent announcements from the company include the ability to produce textured belts up to 2600mm wide and etching techniques that can be used to produce textures as deep as 350 microns - a major advance on previous capabilities.

Wood fibre flooring

Sandvik also continues to cooperate with flooring company Välinge on the development of 'paper free' solid laminate flooring, or 'wood fibre floors' (WFF).

The use of Välinge Powder Technology in combination with Sandvik press plates is designed to deliver a solid surface with exceptional properties in terms of deep embossing, wear/impact resistance, colour variations, design flexibility and mechanical performance. A number of major laminate flooring producers have signed licensing agreements with Välinge and all are using Sandvik press plates.

Meanwhile, Sandvik's capabilities in the wood and furniture market have been further extended by the merger of the composites arm of Sandvik and fellow press equipment manufacturer TechnoPartner Samtronic GmbH (TPS), a move that has resulted in the formation of Sandvik TPS.

The new company - based in Göppingen - is able to offer double belt press systems from low pressure laminators based on Teflon-coated belts to steel belt presses, with processes suitable for the production of a range of flooring materials, including multi-layer tiles and composite products.