Leading the way in design and creativity

20 June 2019Thermally Fused Laminates, or TFL, are one of the smartest environmental surfacing options available and Arclin leads the North American market

Arclin, based in Atlanta, Georgia with facilities throughout the US and Canada, is the premier North American supplier of decorative surface overlays for Thermally Fused Laminates (TFL). Long a staple in Europe, Asia and other world markets, TFL continues to gain popularity in the US as enhanced design, printing and resin technologies continue to grow its application opportunities.

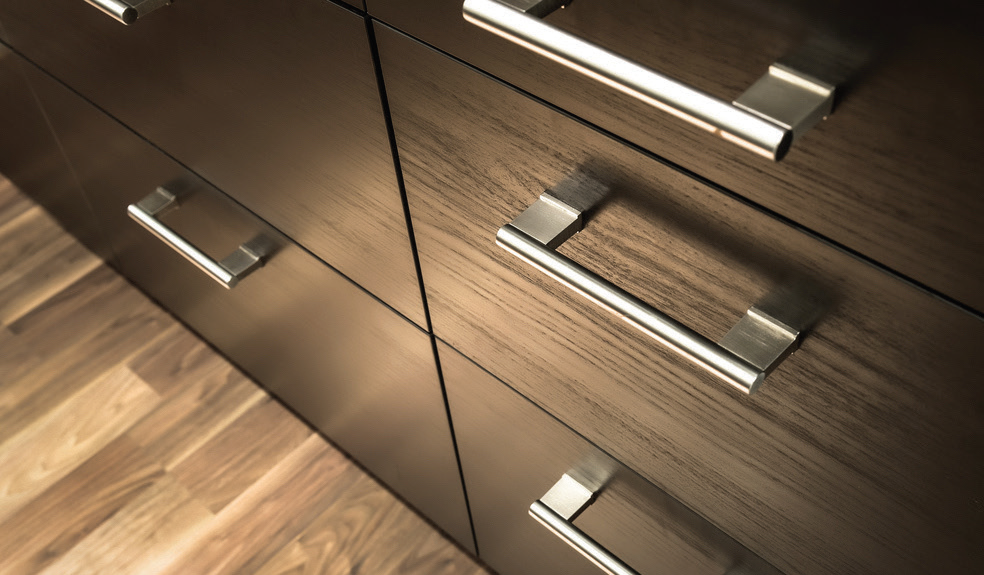

Increased US demand is also being driven by interest in and regulation of green building standards and the acceptance of alternative building materials among millennials. Today, TFL complements wood, stone, HPL and other surface options in high-end kitchens, office environments, hospitals, closets, retail and hospitality spaces, and more.

The most critical element of successful TFL production is the resin systems employed during treating. Arclin uses a proprietary multiple-coat treating process that is key to many of the performance characteristics of the finished TFL panel, including heat and scratch-resistance, water and chemicalresistance, and colour stability.

Increasingly in-demand textures and embossing, created during lamination, are also enabled by additives to the resin system that prevent papers from weakening.

Antimicrobial properties and smudge resistance, too, are resin-dependent. Throughout the manufacturing process, environmental considerations produce an end product that is highly sustainable.

Décor papers meet Forest Stewardship Council (FSC) standards for sustainably harvested fibre sources and printers largely use environmentally friendly water-based inks, Arclin’s plants are FSC chain-of-custody certified and its resin systems meet all CARB Phase II compliance regulations for air quality.

Arclin-overlaid panels may also contribute to LEED credits for air quality as set out by the US Green Building Council.

Paper overlays, which can mimic in design the most sophisticated of wood grains, also preserve trees, especially exotic and other non-sustainably grown species.

While commodity papers (whites, almonds, greys and blacks) continue to dominate the TFL market, the evolution of high-fidelity designs for decorative overlays is creating a surge of demand for highly realistic wood grains, exotic species, abstracts and more. Arclin’s creative team continues to curate the company’s design portfolio to ensure its selection reflects worldwide design trends. Most importantly, the company’s designs are applicationflexible, appropriate for a wide variety of environments.

Among trends leading today’s design selections include:

Rustic Evolution – Rustics have evolved from simple raw structures to reflect a more elegant realism. Ripe for textures, they are found in seemingly every environment where TFL makes its mark.

Bright Lights – where a love for whiteon- whites and bright clean lines are paramount.

Rich Classics - Made Modern – modernised, high fidelity classics. Warm, rich and sophisticated and equally at home in traditional and modern interiors.

Shades of Grey – greys have been on trend for several years now. Today, they are expanded to include warmer colourations and more exotic structural detail.

In addition to interior decorative overlays for TFL, Arclin manufactures EPIC concrete forming overlays for plywood; ReadyPaint and ReadyPrime pre-primed exterior overlays; protective overlays for wood panels, including Firepoint fire retardant LMX weather barrier overlays; and GraphX decorative exterior surface overlays.