IPPS meets COST

7 January 2016Llandudno, an unspoilt seaside town on the beautiful North Wales coast in the UK, was once again the venue for the biennial International Panel Products Symposium (IPPS), which this year included a session on COST Action FP1303: Performance of bio-based building materials.

The drive along the partly mountainous coast of North Wales, and the Regency splendour of Llandudno, never disappoint; and neither did the IPPS programme organised by the BioComposites Centre, a commercial company associated with Bangor University.

European delegates came from the Czech Republic, the Netherlands, Germany, Austria, Switzerland, Greece, Norway, Belgium, Eire, France, Latvia, Poland, Spain, Denmark, Slovenia and the UK.

From further afield there were delegates from Canada, Uganda and South Korea. Apologies to any I have missed, but you get the picture - that this is a truly international conference.

Rob Elias, director of the conference's organiser, the BioComposites Centre, welcomed delegates and talked about the challenges facing the industry, such as changes in regulations; the issue of volatile organic compound release; the skills shortage in the construction sector, particularly in the UK; and the need to include more recycled content in building products.

"My 'soap box' message is that we must raise the profile of the industry and of its social, economic and environmental benefits," said Dr Elias. "We must also develop more networks such as Innovawood to reach out to a far wider audience and there are 10,000 researchers in our sector [to call on]." Dr Elias also talked about the importance to the industry of EC-funded COST Actions, including FP1303 which was to be covered during the symposium. Session 1, Part 1, Fundamental Characteristics, began with a keynote address by Philip Evans of the University of British Columbia, Canada.

The title of his presentation was Probing the structure of particulate wood composites using x-ray micro-computed technology.

The objective was to look at the structure inside particleboard and OSB. In the first case, this was to visualise resin distribution, while in OSB, it was to visualise zinc borate distribution (used to deter fungal growth and insect attack). The rationale of the project was to see if adhesive levels could be reduced whilst maintaining the panels' properties.

"Improved bonding could lead to wood composites with enhanced properties," said Dr Evans. "Maybe even boats or ships could be made from them...."

By rotating the panel samples through 360o over 14 hours, a series of radiographs were obtained and the data fed into a super-computer.

Dr Evans concluded that x-ray micro-CT examination of composite panels is providing insights as to how current composites could be improved (in some cases without increasing costs) by knowing the precise structure of mats during pressing; and that much more is possible, especially in areas of process improvement.

For OSB, he concluded that zinc borate is mainly located in the glue lines and that modification of the adhesive could possibly be used to change the levels of zinc released when OSB becomes wet. He admitted he did not know what happens to the zinc and borate that leaches from glue lines.

He also said that it is now possible to use fast imaging techniques to view the evolution of the structure of a material in seconds. This, he added, is sometimes called "4-D imaging".

The next speaker was Martin Ohlmeyer of the Thünen Institute in Germany. His paper was entitled Effects of refining parameters on fibre quality measured by Fibre Cube.

Dr Ohlmeyer said that fibre quality for MDF production is a "black box" and currently available systems may not meet the requirements of the industry. He said fibre separation is very important, with no bundles or balls.

Dr Ohlmeyer and his team therefore developed a software and hardware system to optimise fibre size measurement. This they called FibreCube and they successfully used it to investigate fibre size distribution and morphology in relation to different wood species and refining parameters.

Surface characterisation of particleboard panels manufactured from eastern red cedar using a multi-sensor approach was the theme for Jakub Sandak of the Trees and Timber Institute in Italy. "Eastern red cedar is an invasive species in the US and we wanted to find a good use for it," explained the speaker.

His team used a VIS-NIR hyperspectral camera to measure colour uniformity and pattern and FT-NIR spectroscopy to determine chemical characteristics of the samples the team made. Surface roughness was also tested by a 3-D laser displacement sensor, while surface wettability was assessed by a sessile drop scanner. Mr Sandak concluded that his multi-sensor methods work in prototype form and have "a great potential to be utilised at an industrial scale".

Opening Session 1, Part 2: Resins and Additives, was Xiaobin Zhao of Cambond Ltd, UK, whose paper was entitled Green glue - biomass-based formaldehyde-free bio-resin for the wood panel process.

"UF resins have good costs and properties so how do we maintain low cost, with recyclability and low emissions?" asked the speaker. "Our solution is our Biomass Cross-linking and Blocking (BCB) technology, which utilises the discovery that algae and Distillers Dry Grain and Solubles (DDGS) in an aqueous medium can be cross-linked by isocyanate-containing cross-linking agents to form a water-resistant polymeric network."

This work resulted in the conclusion that the resin works and has no added formaldehyde, while reducing the amount of pMDI used for MDF and particleboard manufacture.

"No major process changes are required to use this resin," concluded Mr Xiaobin. Andrew Abbot of the University of Leicester in the UK presented Starboard: MDF derived from starch. He said that starch is a naturallyavailable biopolymer which can be plasticised in a novel way using salts known as Deep Eutectic Solvents (DES).

Sources of thermoplastic starch composites include egg shells and wood flour - both readily available - while egg shell waste from the food industry is available in very large quantities.

Starboard has already been used in making point-of-sale furniture and one manufacturer claimed it glued better than conventional MDF. It is also fully recyclable/compostable and has no added formaldehyde.

The next paper was by Byung-Dae Park of South Korea, entitled Characteristics of urea formaldehyde resins with a low formaldehyde/ urea molar ratio.

The speaker said that greater understanding of the characteristics of low F/U molar ratio UF resin adhesive is important for developing formulations and processes aimed at minimising formaldehyde emissions from UF resins and that further research is needed to fully understand the properties of UF resins contributing to formaldehyde emissions and panel performance.

The final paper in Session 2 was from Anne Christine Steenkjaer Hastrup of the Danish Technological Institute on The performance of a new water-based fire retardant in wood based panels.

"We needed a bio-sustainable, recyclable fire retardant because some existing chemicals are being phased out for environmental reasons," said Ms Hastrup.

Burnblock was the product used and it was sprayed onto the MDF fibres. While it appeared to be successful as a fire retardent, further work will determine its effect on resin systems.

Session 2 was entitled Feedstocks, recycling and waste materials and was kicked off by Craig Bartlett of MDF Recovery, UK, with his paper MDF: Closed loop recycling - enhancing supply chain value. He said that MDF Recovery's system for recycling MDF back into MDF or insulation bats was patented in 2011 and that a pilot-level scale-up was now underway. He added that this technology would turn a problematic waste stream into a valuable raw material.

Next came WBPI columnist Dr Mark Irle of Ecole Supérieur du Bois, France, with his paper Extracting high-value products from waste MDF. His paper offered a different solution to the previous paper on the waste problem of used MDF - using it as a raw material for the manufacture of nano-crystalline cellulose (NCC). He concluded that high-value NCC can be made from the large quantities of waste MDF available, but the process needs to be optimised. Partial liquefaction as a method for cleaning waste wood was the title of Sergej Medved's paper. He came from the University of Lubljana in Slovenia. His team found that partial liquefaction can be used to remove heavy metals from waste wood and that the material obtained could be used to make particleboard.

The next speaker was Michael Kyriazopoulos of Bern University, Switzerland and his paper was entitled Development of medium and low density fibreboards made of milled coconut husk and bound with formaldehyde-free tannin-based adhesives.

The coconut husk was found to contain high levels of lignin and extractives, with the diffuse presence of silica particles on the fibre surface. Boards of both 800kg/m3 and 250kg/m3 were produced, both meeting relevant Japanese JIS standards. The idea was to use such boards as locally-available, affordable building materials to address the acute housing shortage in the Philippines.

The impact of blue stain-infected spruce on particleboard properties was the theme of the talk by Martin Weigl of Wood K Plus, Austria. It was found that blue stain has a significant effect on the mechanical properties of spruce-based particleboard due to altered resin penetration, hence the degree of blue stain infection needs to be assessed, with electrical conductivity of extracts (EER) being a valuable method for quality control.

An enjoyable gala dinner was held on the evening of the first day, enlivened as usual by the BioComposites' IPPS quiz.

Day two began with Session 3: Durability and performance. The keynote speaker was Callum Hill of the Norwegian Forest and Landscape Institute, and an alumnus of Bangor University, whose subject was The environmental impact of wood compared to other building materials - the impact of European Standard EN15804. The speaker pointed out that life cycle analysis (LCA) is increasingly being used by all suppliers of building materials to endorse their products.

However, he said that LCAs are very complex to conduct and do not allow valid comparisons between different products and this has produced a tendency to grossly over-simplify the results into a single 'impact factor'.

This has led to the introduction of environmental product declarations (EPDs) for which the LCA calculation rules are defined. Dr Hill's work looked at EPDs, with the emphasis on wood based composites.

He concluded that one has to be cautious when making comparisons between different materials; that the only fair comparison is with a functional unit; and that timber products are always superior when the sequestered carbon is taken into account - they all have a negative carbon footprint.

However, Dr Hill did caution against denigrating concrete out of hand, saying that the material is not bad in itself, but the problem is that it is used in large quantities. Not so steel, which he described as just "bad".

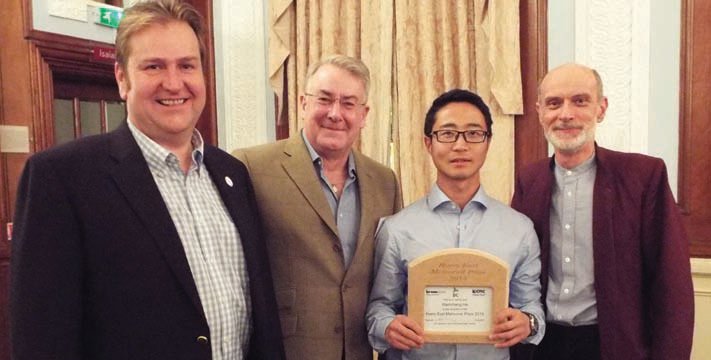

Fresh from his success in winning the Harry Earl Memorial Award, presented for the first time at the annual dinner, Wenchang He was the next speaker to take the stand. The award was set up in memory of Dr Harry Earl, who made a lifetime's contribution to the panel industry and who sadly passed away in October 2013 at the age of 62. It provides a £500 bursary to support travel and training requests from students and early-career people in the panel industry and is sponsored by CRC and by Kronospan UK.

Returning to Wenchang He's presentation, his title was: Reducing the thickness swelling of wood composites by creating a 3-D adhesive network. The hypothesis was that panels have good X and Y (longitudinal and transverse) connections in the adhesive, but poor connections in the 'Z' (thickness) direction. This leads to a tendency for thickness swelling.

Veneer samples were used in the experiments, with micro-holes drilled through their thickness to encourage Z cross-linking.

The researchers found that good cross-linking in the Z direction did indeed generally reduce thickness swelling, with differences between veneer species. Wenchang He suggested that spiked rollers incorporated into a plywood veneer line could be used to perforate the veneers and he is working on a similar system for OSB strands/flakes.

Staying with plywood, Juris Grinins of the Latvian State Institute of wood Chemistry, looked at Thermo-hydro treated birch plywood with improved surface properties.

The team treated birch veneers and then made them into plywood panels. They also treated plywood itself.

In both cases, they found that with increasing treatment temperature and time, the dimensional stability and biological durability of the reference plywood were improved.

However, a loss in bending strength and hardness was also observed due to destruction of hemicellulose.

Various treatment temperatures were tried and it was found that 160oC for 10 minutes was almost perfect, according to Mr Grinins. Times of 50 minutes were found to produce a serious loss of mechanical strength. Research continues. Cihat Tascioglu of Duzce University in Turkey presented Biological performance of post-treated wood based composites under protected aboveground conditions.

The objective was to examine the feasibility of post-treatment of composite panels, including hardwood and softwood plywood, MDF, OSB and particleboard. Exposure was for three years at a Japanese field test site.

The team concluded that MDF displayed high natural decay and termite resistance, even when untreated. Post-treatment with ACQ and CA at the retention levels tested showed significantly enhanced termite resistance in softwood and hardwood plywood - and in OSB and particleboard - compared with untreated controls.

The next speaker was Bronia Stefanowski of host company, the BioComposites Centre.

She had investigated The sorption of VOCs by modified MDF panels and the effects on mould colonisation and growth. This research concerned the problems of indoor air quality (IAQ) with increasingly tightlysealed buildings, producing 'sick building syndrome'. It used organic scavengers, namely peanut and walnut shells, to actually absorb formaldehyde and VOCs from the surrounding air into panels.

It was found that boards treated with either scavenger did absorb VOCs, but also had increased vulnerability to mould growth, more in the case of walnut shells than peanut shells.

Investigating plywood behaviour in outdoor conditions was presented by Wanzhou Li of the University of Ghent, Belgium. The aim was to increase water resistance of plywood by optimising its structure and to examine this by the use of neutron radiography for moisture; and x-ray computed tomography for the internal structure.

The team found that veneers with good water resistance and durability should be used in the outer faces, while those with lower water resistance but good strength properties can be used for the inner layers. Care should be taken when peeling veneers to minimise veneer checks and control the veneer direction so it is parallel to the face direction.

The next paper was presented by Martin Riegler of Wood K Plus and was entitled Potential of granulated maize cobs as a substitute for particleboard production.

The corn cob granules were mixed with wood particles in the construction of single layer particleboards in varying amounts.

It was concluded that the addition of 20% maize cob granules led to slightly decreased mechanical properties. Further research into particle sizes is being carried out.

Session 5 concerned COST Action FP1303 on bio-based building materials and is the subject of the following article in this magazine.

The 2015 edition of IPPS was well attended by a mix of delegates from many different countries and disciplines, including representatives from panel manufacturing companies and suppliers to those businesses.

It gave those delegates wide-ranging subject matter and while much of that was inevitably of a scientific nature, it is science that makes the difference between good and bad panels - and between loss and profit for the panel manufacturers.