Bio-based building

7 January 2016On the occasion of the IPPS conference in Llandudno (see report on previous pages), members of COST Action FP1303, bio-based building materials, were invited to present their work to date.

The COST Action programme was instigated by the European Union in 1971 as a "flexible, fast, effective and efficient networking instrument for researchers, engineers and scholars to cooperate and coordinate nationally-funded research activities. These COST Actions (CA) allow European researchers to jointly develop their own ideas in any science and technology field".

Dennis Jones of SP Wood, Sweden, and chairman of FP1303, explained to the delegates at the biennial IPPS conference the reason for this particular COST Action, FP1303, which is in fact designated an FPS (Forests, their Products and Services): "An FPS has the mission to promote research along the whole forest wood chain by providing a platform for effectively coordinating nationally-funded research activities in the areas of forestry, wood technology and pulp and paper," said Dr Jones. It also includes the production of bio-energy from forests.

The speaker described to the audience what exactly a COST Action is.

"Each COST Action is set up in a way to help promote research and cooperation with national experts from each participating country (nominated by their country to COST) who act as information providers to their country, ensuring widespread dissemination of information," continued Dr Jones.

He went on to explain that the CA organises regular workshops/conferences and specialised meetings on subjects related to ongoing activities in the Action and provides a range of activities, aimed in particular at Early Career Investigators (formerly known as Early Stage Researchers), who gained their Phd within eight years of the start of the Cost Action. The final workshop for CA FP1303 will be held in Sweden in 2017.

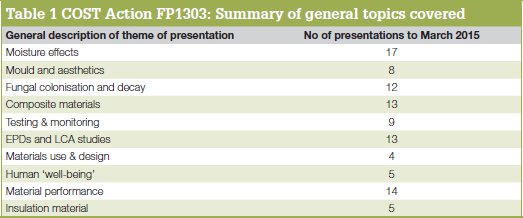

Meetings held as part of a CA include Management Committee meetings to define the particular CA strategy; Working Group meetings focusing on the work in the scientific objectives of the CA; Core Group meetings to help prepare management committee decisions; Action Workshops/ Conferences open to the scientific community to showcase the activities of the CA; Dissemination meetings, where a maximum of two delegates per grant period attend other conferences; and the final Workshop/ Conference to report the CA's achievements. Table 1 on the following page summarises some presentations given during the course of this CA.

There are also Short-term Scientific Missions and these are designed to benefit young scientists from a country that has joined the CA.

Finally, there are Training Schools which provide intensive training on a subject that contributes to the aims of the CA and fixed grants are paid to the trainees from COST participating countries. With 20-30 trainees and two to three invited trainers, the schools combine theory and practical work.

Returning to CA FP1303, Dr Jones explained the motivation for this particular COST Action. "The key role of FP1303 is to raise awareness across the wider scientific community and associated industries of the potential [for] using wood and plant fibre products where performance and service life are critical parameters. It is about increasing building performance in matters such as controlled air exchange, limited heat loss, greater thermal efficiency of building design and advancing issues related to indoor air quality (IAQ).

"This COST Action will help address issues across the following themes: Societal; environmental; impact on human health; and scientific," Dr Jones continued. "In order to achieve these activities, COST FP1303 has been split into three working groups (WGs): Material capability and enhancement; Functionality and performance; and Adaptation and applications."

The first WG is dedicated to the fundamental understanding of the interaction between decay organisms and the substrate. The second aims to concentrate on the suitability of bio-based materials in terms of their overall performance, identifying issues that affect their service life (eg fibre-moisture relationships and moisture, heating, etc in buildings). The third WG gathers knowledge about preferences within industry stakeholders and end-users; and tools used in assessing environmental performances (eg life-cycle methodologies, EPDs and CE markings).

"The development of non-wood particleboards has been a key feature of recent meetings" said Dr Jones. "Among species that have been studied and reported within the Action are sorghum and hemp shives, with the latter demonstrating improved bending strengths compared with unmodified particleboard, when incorporated as a core material.

"While other Actions have focused on decay prevention, had a material focus and been based on wood only, FP1303 has a wider materials range; is based on materials in use; is stakeholder driven; and involves material acceptance and consumer preference."

Specific outcomes intended from this CA, said the speaker, are to establish and maintain a database of performance of natural building materials; to provide guidance on material use and maintenance; to generate and make available online reports and documents for advancing education and codes/standards; to bring together knowledge of previous and ongoing COST Actions; to have focused outputs aimed at producing codes and standards; to create focus groups for material combinations/ performance in service; to develop a pan- European approach to how natural building materials are used.

Several presentations were given at IPPS by COST Action participants. The first was by Daniel Stratev of Holzforschung Austria. His subject was From model rooms towards a modelled indoor environment. He concluded that a Quality By Design (QBD) approach could be applicable by the emissions health assessment of construction products.

Next, Sergej Medved of the University of Lubljana, Slovenia presented his paper Formaldehyde and total volatile organic compound (TVOC) emission in a wooden model house. He concluded that: Indoor conditions influence the indoor formaldehyde and TVOC concentration; in the first period only (two weeks), a correlation with indoor temperature was determined; in the second period (four weeks), correlation of indoor temperature and humidity were determined; and an increase in EMC resulted in an increase in formaldehyde and TVOC concentration.

The third presentation was by Mark Lawther of the Danish Technological Institute: Emissions and sensory testing of straw and non-wood fibre based panels. His principal conclusion was that boards produced from straw and tomato stems do not give rise to hazardous levels of emissions, although odorous compounds are released. These odours were judged "just unacceptable" by a panel of volunteers, even after four weeks.

The next presentation was by Jorge Galván of Centro de Investigación Forestal, Spain: Durability of Maderon®, a non-wood composite, against wood decay organisms. Maderon is made of almond shell flour and was found to be durable against attack from all the wood decay organisms studied. After the coffee break, Edgars Kuka of the Latvian State Institute of Wood Chemistry presented Wood plastic composites made with thermally modified birch wood residues.

He concluded that the thermally modified residues were indeed successful in WPC production, although the thermal modification (TM) did influence the properties of that WPC. However, all the tested properties except impact strength were better for WPCs with TM wood fibres compared to those made with unmodified wood fibres.

The addition of the COST Action session to the IPPS symposium not only attracted some extra delegates, but also provided an interesting insight into the purpose of these Actions and their relevance to the wood based panel sector.