A unifying voice

13 July 2016Jackson Morrill is the president of the Composite Panel Association in North America, overseeing an organisation which represents the vast majority of MDF and particleboard manufacturers on that continent. Mike Botting speaks to Mr Morrill about his role, the role of the CPA, and his aspirations for the association

The Composite Panel Association (CPA) was founded in January 1960, holding its inaugural meeting in Chicago. The purpose of the organisation – and its nine representatives at that time – was to establish national product, and industry, standards, to deal with customs classification and international trade issues, and to establish communications and advocacy with Federal agencies.

The full-time president of the Association is Jackson Morrill, who commenced his role in April 2015.

“Over the years, we have not strayed far from those original objectives,” says Mr Morrill. “Though we have added some other functions, such as formaldehyde emission testing and certification; and a marketing role.”

The CPA also brings together the complete value chain affiliated with the composite panel industry. It says its members are committed to product advancement and industry competitiveness.

Associate Members include manufacturers of decorative surfaces, furniture, cabinets and doors and mouldings, as well as resin suppliers, laminators, distributors and equipment suppliers.

“We are a member-led organisation,” explains the president. “We have industry leadership people serving as officers on our board, which oversees our activities, while on the full-time staff of the CPA, there are 11 people, including me.”

Mr Morrill was not always employed in the panel, or even wood products, industry, but has a working background which he has found useful and relevant in his current role: He is an environmental lawyer and has worked on the American Chemical Council, where he ran the formaldehyde panel.

“The formaldehyde panel was like a ‘mini-trade association’ and my role was similar to that which I have now,” says the president. “I also worked closely with the CPA, the California Air Resources Board [CARB] and the Environmental Protection Agency [EPA] on formaldehyde emissions regulations.

“Within the CPA, I also manage the Environmental and Public Policy committees and the organisation of the Spring and Fall [Autumn] members’ meetings.

“We have a highly-regarded formaldehyde testing facility and of course we are the ‘voice of the industry’ which I am honoured and excited to be serving.”

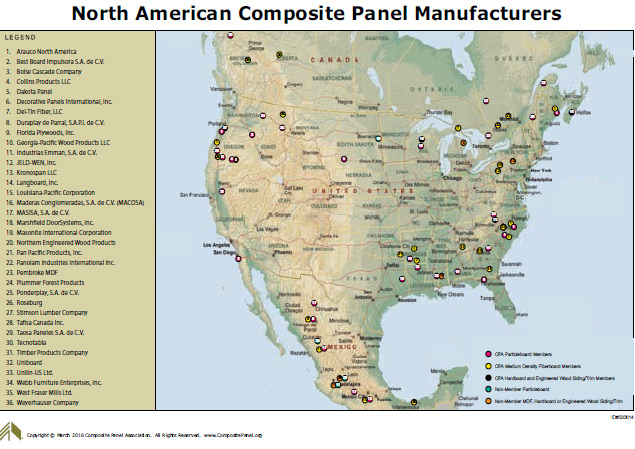

The panel-manufacturing membership of the CPA accounts for 95% of the particleboard, 100% of the MDF and 50% of the hardboard producers in North America.

“Those members comprise 30 particleboard, 20 MDF and five hardboard producers. The latter are mostly in engineered wood siding and trim for exterior use,” points out the president.

“We also have a robust associate membership of 142 organisations which span the supply chain and include resin and resin equipment manufacturers, distributors, laminators, furniture makers and kitchen and shopfitters. We also have nine members from academia and several journals represented [including WBPI].

“Our associate membership has grown by 15% since 2013 and that is pretty good – and we have a good retention of members,” says Mr Morrill.

Of course the CPA is not alone in the panel arena. There is the Structural Board Association and APA-The engineered wood association, representing OSB and veneer based products, respectively.

“I see these organisations as offering the opportunity for improved coordination: There are a number of activities that we could leverage-up between us, for example hiring the next generation of the workforce. This is an acute situation and it is currently difficult to attract the ‘millennials’. This represents a classic opportunity for these wood associations to come together,” says Mr Morrill.

“For instance, CARB [regulation] has hit all sections of the industry and we have taken the leadership role, not only in the technical work, but in convening industry coalitions of all the impacted associations to move together. This has been very effective. We also have broader coalitions, with NGOs, the community and the unions.”

There has been a lot of regulatory pressure on the panel industry for the past few years now, but the president seems more than OK with that.

“Hey, we’re ready to be regulated and some regulation is good for everybody. We are coming to a conclusion on that with the EPA and encouraging them with regard to enforcement and achieving a ‘level playing field’ across the country; the EPA should have a strong enforcement role.”

The CPA is as concerned about the biomass issue as is the European Panel Federation (EPF) in Europe, says Mr Morrill.

“We are following [what is going on in] Europe closely and had the EPF's technical director, Kris Wijnendaele, at our Spring meeting in April. We’re very concerned about subsidies and mandates, too – we’re saying those subsidies should not be there. We sequester carbon – we make something that lasts – and that needs to be recognised.

“We are ‘late to the party’ over here and therefore the EPA has been able to look more carefully at how biomass is used, leading to more-informed decisions. The CPA incorporates forestry owners, sawmill owners and panel makers, so we bring a different approach to the table as we are always trying to align those interests.” “The recent Spring meeting produced a new three-year strategic plan for the CPA, with three main goals,” explains the president. These are:

1. Advocacy – leadership in formaldehyde issues, availability of wood fibre, defence of the industry; being proactive in stewardship;

2. Encouraging enforcement globally for a level regulatory playing field and encouraging the EPA and CARB to police it better.

3. Message and marketing – highlighting our sustainability as an industry and our design attributes. Carbon sequestering, recycling wood residues, formaldehyde resin technology – we’re already at the levels of natural wood and we need to get this out there. Also, trying to do something about engaging the interest of the next generation of workers.

“We will now develop action plans for each of those goals,” says Mr Morrill.

When it comes to communicating to its members, the president says that the Spring and Fall meetings are two of the CPA’s most valuable assets.

“We have put a lot of effort into improving the range of speakers at these meetings, including retailers, suppliers; and other overseas organisations like the EPF, which has always been a speaker there.”

I ask the president what he sees as his personal role in helping the CPA to achieve its objectives.

“I see myself as responsible for measuring up to the goals of our members in all areas, including the three-point plan,” says Mr Morrill.

The recent years of recession have obviously impacted his members and I ask him about those challenges.

“I do think we experienced tail winds last year and a feeling that the economy was picking up. Then China, Brazil, the currency problems and the low oil prices came along. Overall, industry shipments were up 3% in 2015. Our Q1, 2016 shipment numbers appear to be holding up despite those "headwinds". Year-to-date particleboard shipments are up 0.2% (so holding steady). MDF is up 4.4% year-to-date and TFL is also showing decent gains, up 2.2% year-to-date. Whether this pattern will hold, given all the continued economic uncertainty, is a tough question to answer, but certainly we are pleased that the industry continues to show growth, albeit somewhat slow and steady,” says the president.

“We have to be more adept [as an industry] at seeing how markets are changing and in tailoring ourselves to the growth areas. However, the long view is good, as reflected in the recent investments in new lines and upgrades. For instance, Grayling, Michigan [Arauco North America], will be the first new particleboard mill built in the US in 20 years.”

Finally, I ask Mr Morrill how he sees the CPA developing in the coming years.

“The CPA will continue to be a vital and unifying voice throughout the industry,” says the president. “With the global economy as it is, we need to evolve with each new development – for instance in resins – as each one changes the demands; we have to evolve.

“We will continue to play to our strengths in advocacy, marketing, reporting of statistics and so on. And our Spring meeting attendance was the best we’ve seen in 10 years, which brings together the whole supply chain. We had a separate meeting with our Mexican and Canadian members and we are trying to do more for them. I also attended the ANAFATA [the Mexican association of wood based panel manufacturers] Fall meeting last year and will do so again.

“It is a great position to be in [for the CPA], to be leaders in what we do – that is a real strength.”