A question of fibre

31 March 2015My research is generally applied research and closely linked to industrial problems. Sometimes, however, fundamental data is required. I am currently involved in a project called ECOMATFIB. The aim of the project is to develop novel fibre-based products.

The project consortium contains groups of researchers that are going to model the behaviour of different fibre networks. In order for them to do this accurately, they need data on the physical and mechanical properties of the fibres.

The thermo-mechanical pulping process (TMP) is the most common method for producing the fibres needed within the sector. The process generates a wide range of fibre sizes. This is partially caused by the different cells which make up wood, but is mainly because not all the fibres are completely separated during refining.

Consequently, many of the fibres used to make board products are actually bundles of cells still stuck together, but, because they are rather small and long compared to their thickness, they are termed fibres within the industry.

I and some of my students are trying to characterise different fibre samples. They differ in that they have been made using different energy inputs during refining. Some are therefore quite coarse in appearance and others are very fine.

Part of our characterisation involves the tensile testing of single (in an industrial sense) fibres using a micro-tensile test machine that can be installed in the chamber of our electron microscope.

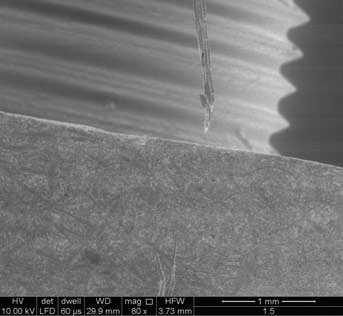

The fibres are, of course, small and this makes the preparation of a test sample time consuming, fiddly and prone to errors. Our approach is to use two drops of superglue to fix a fibre to a paper support that is nearly cut in two. The paper support makes it possible to position the fibre in the test machine. Once there, we cut the remaining part of the paper support so that the fibre is the only connection between the two halves of paper (see Figure 1).

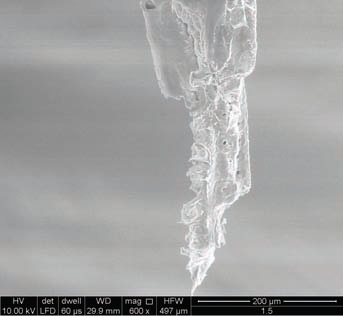

The chamber is then closed and a partial vacuum applied so that electron micrographs can be obtained (see Figures 2 & 3). The vacuum causes the fibre to dry and so we observe some tensile stress development in the fibre as it shrinks.

It is not always easy to see the test fibre because it and the paper support have the same electron density and so there is not much contrast between the two. The images are sufficiently clear, however, to show that the fibres often consist of a number of cells. We have not yet obtained enough data to see any patterns in the way fibres fracture, but we are hoping that we will.

We should also be able to obtain some data on the compression behaviour parallel to the long axis of the cell too. It is likely to be complicated because the fibres are going to buckle during the test. Still if it was easy, then it would not be research.